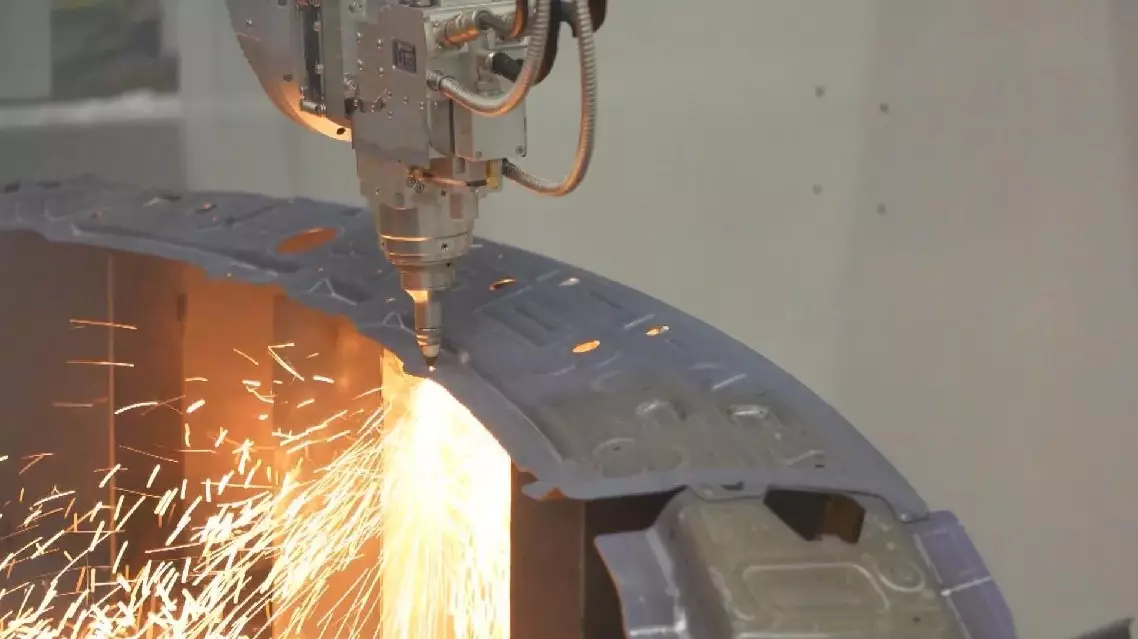

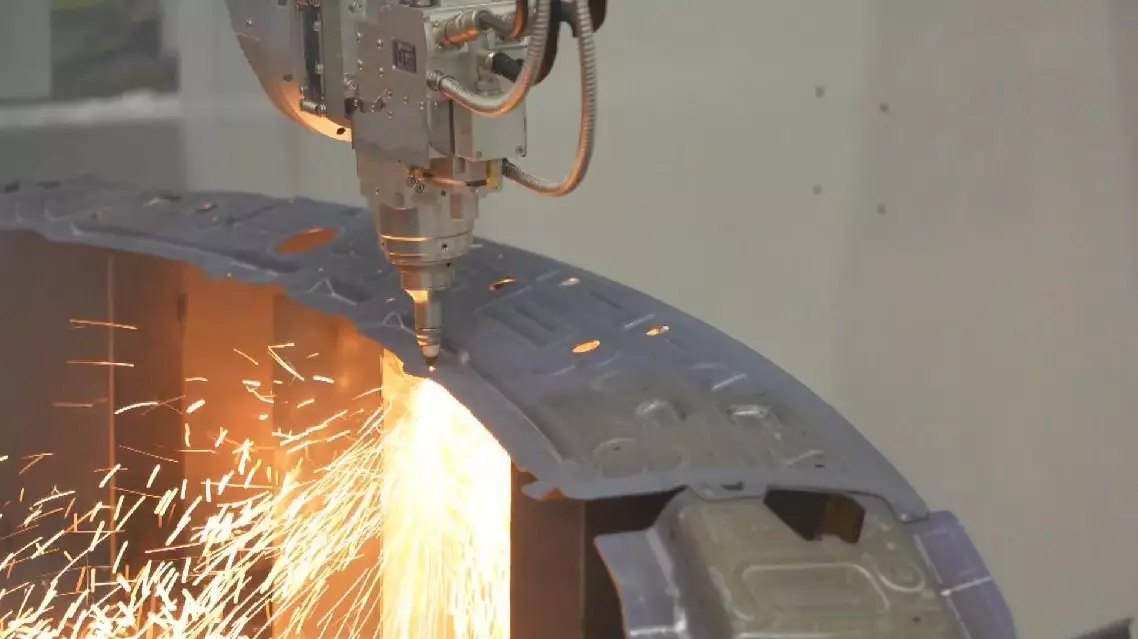

Chinese companies have managed to make breakthroughs in laser cutting machines, as part of the country's efforts to expedite the achievement of high-level sci-tech self-reliance.

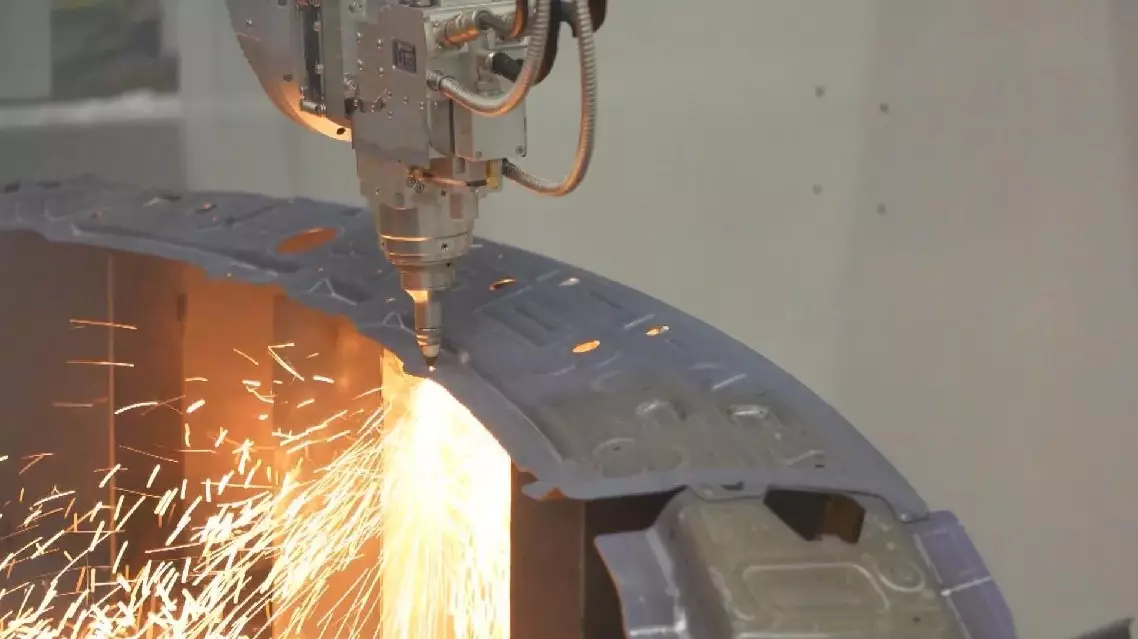

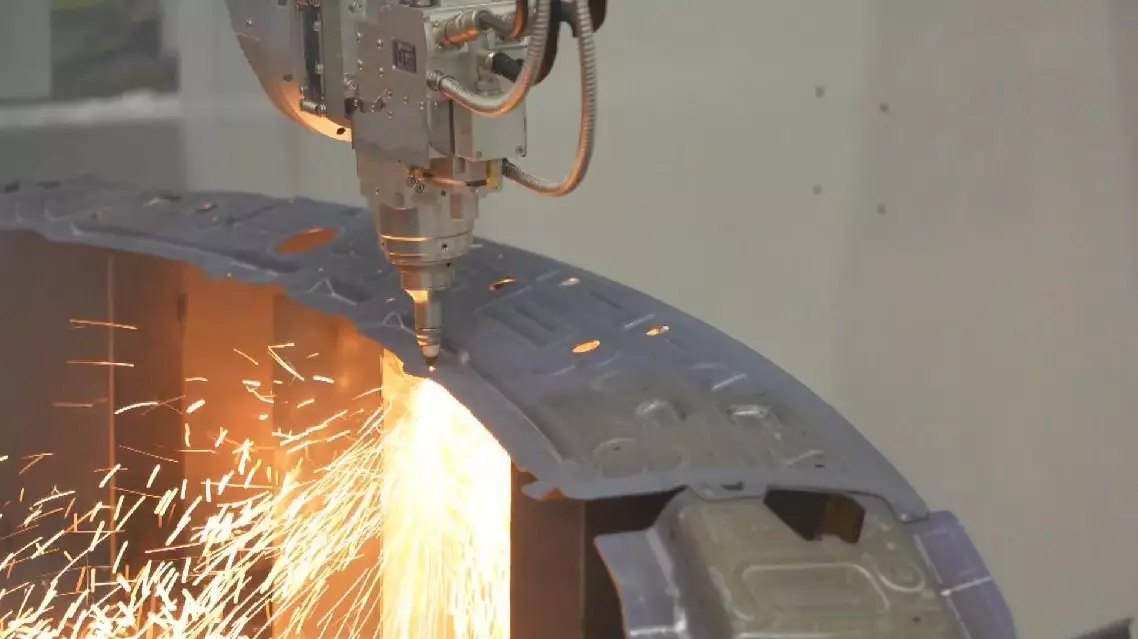

A 3D 5-axis laser cutting machine is capable of rotating 360 degrees and cutting materials continuously, making it the top machine tool in the world's laser industry.

Twelve years ago, the production technology of such machines was monopolized by foreign countries, and there were few application scenarios.

At the end of 2012, Huagong Technology, which is headquartered in Wuhan City, central China's Hubei Province, and specializes in developing, manufacturing and distributing laser equipment, became keenly aware of the importance of self-dependency of 3D 5-axis laser cutting machines, as new energy vehicles emerged on the horizon.

"A key bottleneck facing new energy vehicles is that they must be lightened because they are electric. To reduce weight, high-strength steel plates must be used. High-strength steel plates cannot be processed by traditional stamping presses. Later, we launched a project. Only 3D 5-axis laser cutting machine can meet customers' requirements," said Ma Xinqiang, chairman of Huagong Tech.

Once starting research and development, Huagong Tech found quite a few bottlenecks in technologies.

With the help of the government, Huagong Tech, which was expert in laser cutting head technology, joined hands with counterparts HuazhongCNC and Raycus, which were proficient at CNC system and laser technologies respectively, to work on 3D 5-axis laser cutting machines.

"If Huagong Tech did not put forward such high requirements for product technology and the uniqueness of the industry, we might not have sought to make breakthroughs from underlying technologies. At first, a machine with power ranging from tens of watts to 500 watts and 1000 watts, was considered to be incredible. But later with technological breakthroughs, the machine's power could reach several kilowatts, tens of thousands of watts, and even hundreds of thousands of watts," said Li Jie, deputy general manager of Raycus.

With the continuous advancement of the research and development of 3D 5-axis laser cutting machines, the government supported the three companies to take the lead and organize more than 100 enterprises and scientific institutions to jointly tackle challenges.

After several years of hard work, in 2022, a wholly domestically-produced 3D 5-axis laser cutting machine made a debut, with features superior to that of foreign brands in many aspects. For example, the B-pillar cutting of a car is typically completed in 42 seconds, while the Chinese-made machine can shorten the time to 38 seconds.

The machine broken down market monopolies and won wide recognition.

"We have had a domestic market share of about 70 percent, and our total sales should rank the first worldwide," said Ma.

China makes breakthrough in developing laser cutting technology

China makes breakthrough in developing laser cutting technology

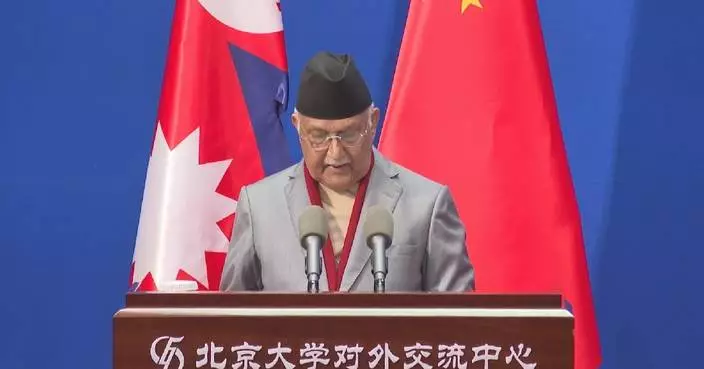

China and Japan should work together to promote stable, lasting bilateral relations, and to uphold regional and international peace and stability, said China's top diplomat Wang Yi in a video speech at the 20th Beijing-Tokyo Forum on Wednesday.

Wang, a member of the Political Bureau of the Communist Party of China Central Committee and director of the Office of the Central Commission for Foreign Affairs, noted that China and Japan have an exchange history of more than 2,000 years, and that it has been over 50 years since the normalization of diplomatic relations between the two countries.

A China-Japan relationship with the right development direction is not only of great and positive significance to both countries and their peoples, but also to the peace and development of the region and the world, he said. Both sides should be guided by the important consensus reached by the leaders of the two countries, adhere to the original aspirations of relations, follow the right path, seek common ground, and coordinate actions, all with the aim of promoting stable, lasting bilateral relations, he said. Noting that the two sides should understand the correct positioning of bilateral relations, Wang said China has always regarded Japan as an important cooperation partner, and hopes that Japan can view China's development objectively and rationally.

It is hoped that Japan will work with China to follow the correct positioning of the comprehensive advancement of the strategic, mutually beneficial relations between China and Japan, and implement the important consensus that the two countries should be cooperative partners and should not pose a threat to each other, he said.

The two sides should maintain the political foundations of bilateral relations. The four political documents between China and Japan have laid the political and legal foundations for bilateral relations, and they should not be blurred, retrogressed or undermined, Wang said.

China and Japan need to promote an open strategy of mutual benefits. Both sides should cherish their cooperation space and common interests that have already been established, and work together to maintain the stability and smooth operations of the global free trade system and industrial and supply chains, he said. Wang also called on the two countries to uphold regional and international peace and stability. In the face of rising unilateralism and protectionism, China and Japan need to work in tandem to safeguard Asian unity and cooperation to prevent external forces from fomenting confrontation, he said.

It is hoped that the Beijing-Tokyo Forum will continue to promote candid exchange, build consensus, provide suggestions for China-Japan relations, and make new contributions to the development of China-Japan relations that meet the requirements of the new era, he said.

Launched in 2005, the Beijing-Tokyo Forum is an annual event held alternately in Beijing and Tokyo. The forum is a high-level, large-scale, interactive exchange platform between the two countries.

China's top diplomat calls for joint efforts to promote stable, lasting China-Japan ties