The launch ceremony for the documentary "Taste of Hong Kong", which showcases the unique charm of Hong Kong's culinary culture, was held in Hong Kong on Thursday.

Jointly produced by China Media Group (CMG) and Radio Television Hong Kong (RTHK), the documentary offers viewers an immersive experience of the distinctive culinary culture of the "Pearl of the Orient" from 10 different aspects.

The documentary is available in Mandarin, Cantonese, and English.

Chief Executive of the Hong Kong Special Administrative Region (HKSAR) John Lee welcomed the partnership between CMG and Hong Kong media, noting that it could help integrate the city into the country's overall development while promoting Chinese culture to the international community.

Furthermore, the event also marked the launch of a video collection and screening activity titled "My Chinese Heart", which aims to capture the experiences of Hong Kong youths in understanding their national identity.

Hong Kong's culinary culture takes center stage in 'Taste of Hong Kong' documentary

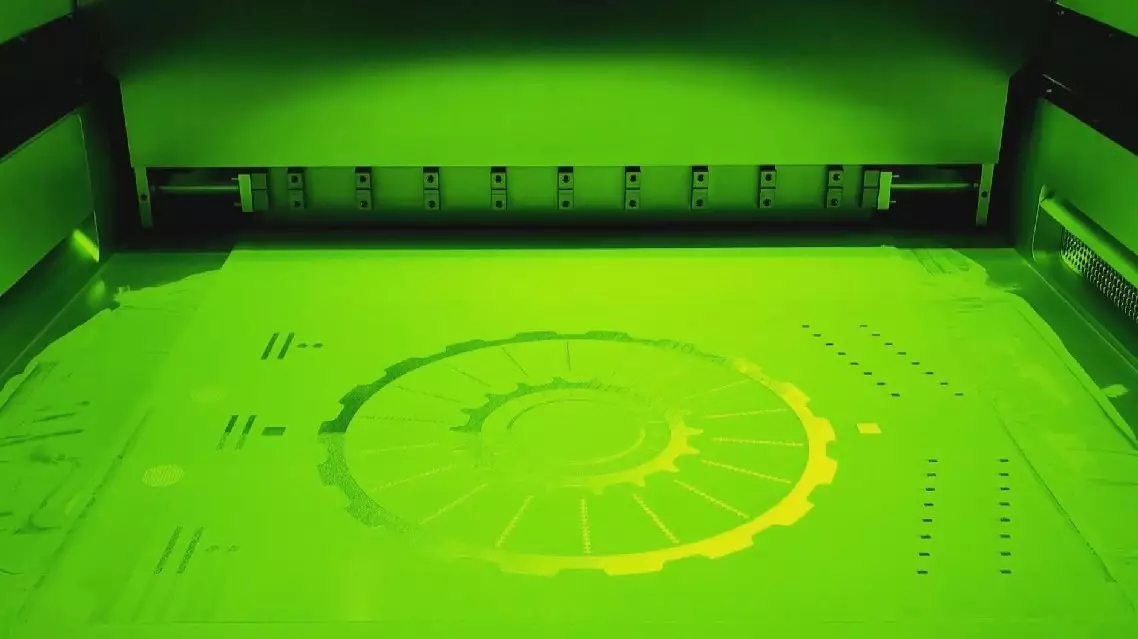

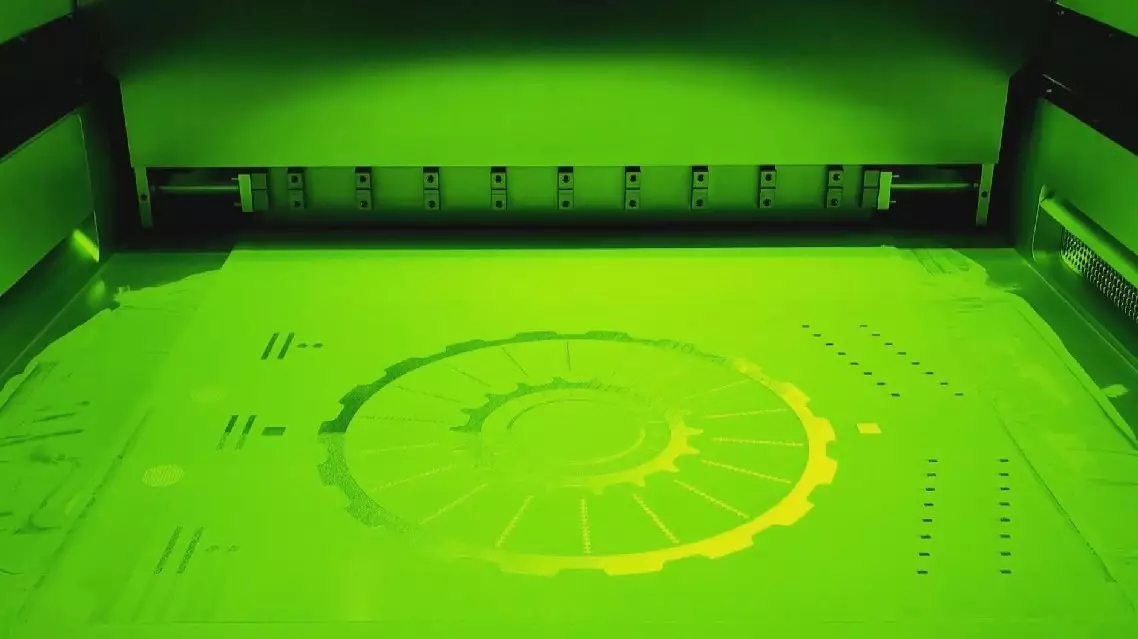

Researchers at a laboratory in Foshan City, south China's Guangdong Province, have deepened their research on metal 3D printing technology, also known as metal additive manufacturing, to upgrade the traditional materials manufacturing industry.

Metal 3D printing is a laser-based technology that constructs objects layer by layer by fusing metal particles. It employs heat or light energy, such as a laser or electron beam, to melt or bond the metal powder, spreading it over previous layers.

According to a researcher at the Institute of Advanced Additive Manufacturing of Ji Hua Laboratory, 3D printing has a great advantage in fabricating arbitrary shapes without any limitations and has great potential in preparing controllable porous structures.

"In traditional methods of processing, we need to produce these channels first and then weld them at the corresponding points, which can result in tiny welding defect pores in the welding area. However, 3D printing completely avoids the possibility of welding defects because it is integrally formed. Our whole industry is gradually developing in the direction of larger sizes, more lasers, and higher efficiency," said Gao Chaofeng, doctoral student at the Institute of Advanced Additive Manufacturing of Ji Hua Laboratory.

Another researcher at the lab pointed out that they aim to make more progress in new material and key components development in some key areas.

"We aim to solve some of the main difficulties in the industry at present, such as improving the quality and performance of products and reducing costs. In the long run, we strive to develop new materials and future technologies in China, especially in equipment such as key components for engines and aerospace fields," said Bi Yunjie, deputy director of the Institute of Advanced Additive Manufacturing of Ji Hua Laboratory.

Ji Hua Laboratory is one of the first four provincial-level laboratories initiated by the Guangdong Provincial Party Committee and the Provincial Government. Since its establishment more than six years ago, the laboratory has mainly focused on new display equipment, semiconductor equipment and key components, intelligent robots, high-end medical equipment, advanced remote sensing equipment, additive manufacturing equipment, and new materials and devices.

Chinese scientists leverage metal 3D printing to upgrade traditional material manufacturing industry