As the cotton harvest season is in full swing in northwest China's Xinjiang Uygur Autonomous Region, the region has picked more than half of its cotton, with all expected to be finished in early to mid-November, thanks to the wide application of advanced cotton pickers.

As a major cotton production area in the country, Xinjiang enjoys a high-level mechanization and digitalization in cotton cultivation and picking in recent years.

The state-of-the-art six-row, self-propelled cotton picking and baling machine can seamlessly complete the processes involved in harvesting, compressing and packaging in just about 10 minutes.

The big cotton roll packaged by the machine is called "golden egg" by local farmers in Xinjiang.

"I planted 200 mu (over 13 hectares) of cotton this year, which is expected to produce 45 'golden eggs', weighing about 90 tons," said Wang Feifei, a staff member of Xinjiang Production and Construction Corps.

"It can pick 40 mu of farmland per hour, and 500 mu per day, which is equivalent to the work efficiency of 2,000 workers," said Tan Zengjin, operator of cotton picker.

When working, the cotton picking heads play a crucial role in speed and quality.

"A cotton picker has six heads, which can pick six rows at a time. Each head has more than 500 spindles. Through their own rotation, they pick cotton from shells and then pack it into round bales," said Yang Jianning, director of the Xinjiang Swan Cotton Picker Research and Development Center.

Also known as the "king of agricultural machinery", the cotton picker is one of the most complex machines in agricultural machinery equipment.

After five years of experiment and demonstration, the mass production of the domestic six-row cotton picking and baling machine has been realized in Xinjiang this year, breaking the long-term monopoly of foreign high-end cotton pickers in the Chinese market.

"We've overcome bottlenecks in the core technologies such as seed cotton compression and baling, and the localization rate of the whole machine has exceeded 92 percent," said Duan Qisen, head of Xinjiang Swan Modern Agricultural Machinery and Equipment Industrial Park.

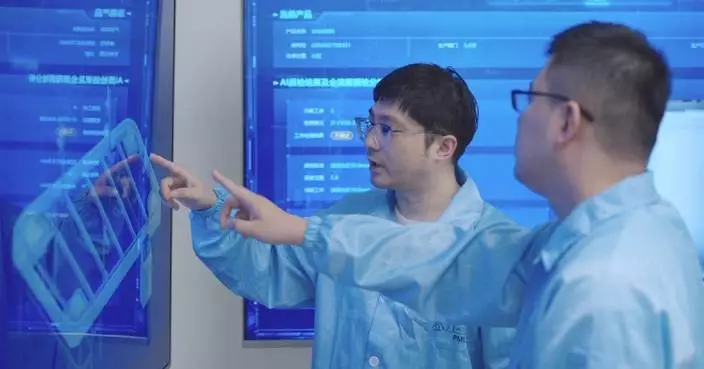

In addition, the harvesting efficiency and post-harvest services have been further upgraded with the support of China's homegrown BeiDou Navigation Satellite System (BDS).

"The performance of homemade cotton pickers is comparable to that of imported ones. With a high harvesting efficiency, each machine can harvest more than 10,000 mu of cotton each season, providing key equipment support for the autonomous and controllable cotton harvesting nationwide," said Wang Jianhong, executive vice president and secretary-general of the China Cotton Association.

Xinjiang finishes over half of cotton picking thanks to advanced cotton pickers

Xinjiang finishes over half of cotton picking thanks to advanced cotton pickers