EAST LANSING, Mich. (AP) — The sight was a common one for Andrew Kolpacki. For many a Sunday, he would watch NFL games on TV and see quarterbacks putting their hands on their helmets, desperately trying to hear the play call from the sideline or booth as tens of thousands of fans screamed at the tops of their lungs.

When the NCAA’s playing rules oversight committee this past spring approved the use of coach-to-player helmet communications in games for the 2024 season, Kolpacki, Michigan State’s head football equipment manager, knew the Spartans’ QBs and linebackers were going to have a problem.

“There had to be some sort of solution,” he said.

As it turns out, there was. And it was right across the street.

Kolpacki reached out to Tamara Reid Bush, a mechanical engineering professor who not only heads the school’s Biomechanical Design Research Laboratory but also is a football season ticket-holder.

Kolpacki “showed me some photos and said that other teams had just put duct tape inside the (earhole), and he asked me, ‘Do you think we can do anything better than duct tape,?” Bush said. “And I said, ‘Oh, absolutely.’”

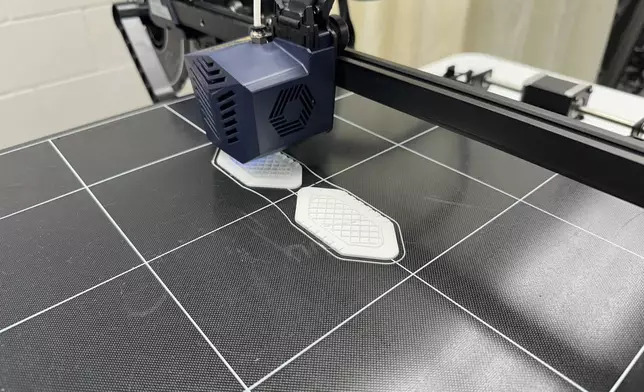

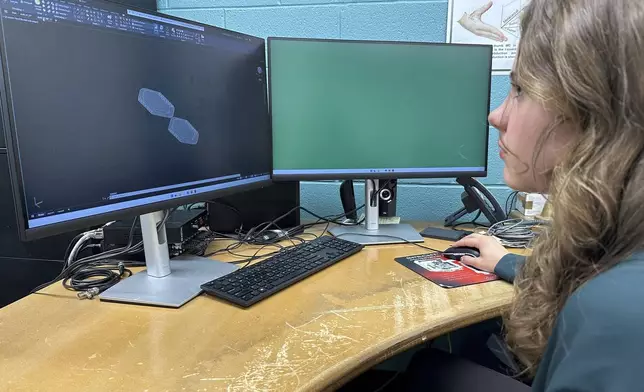

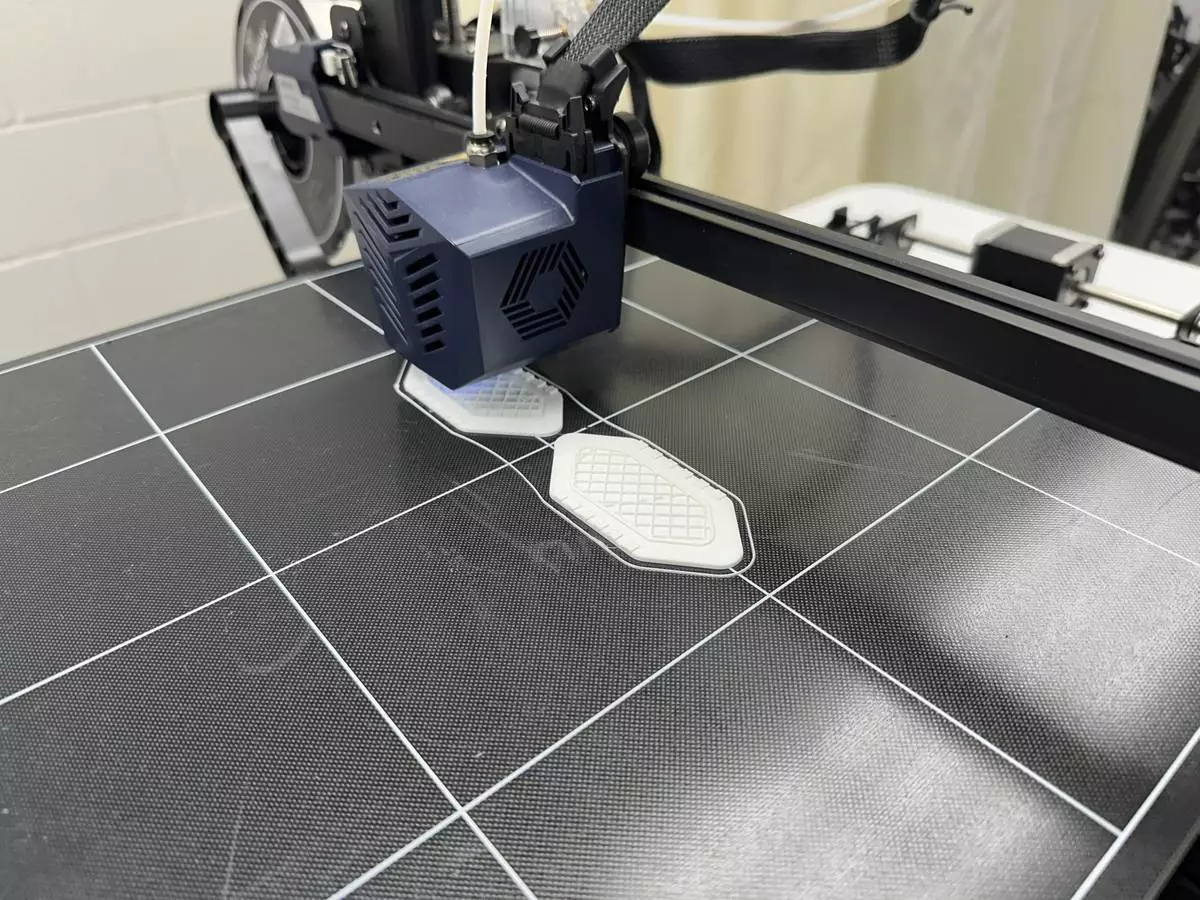

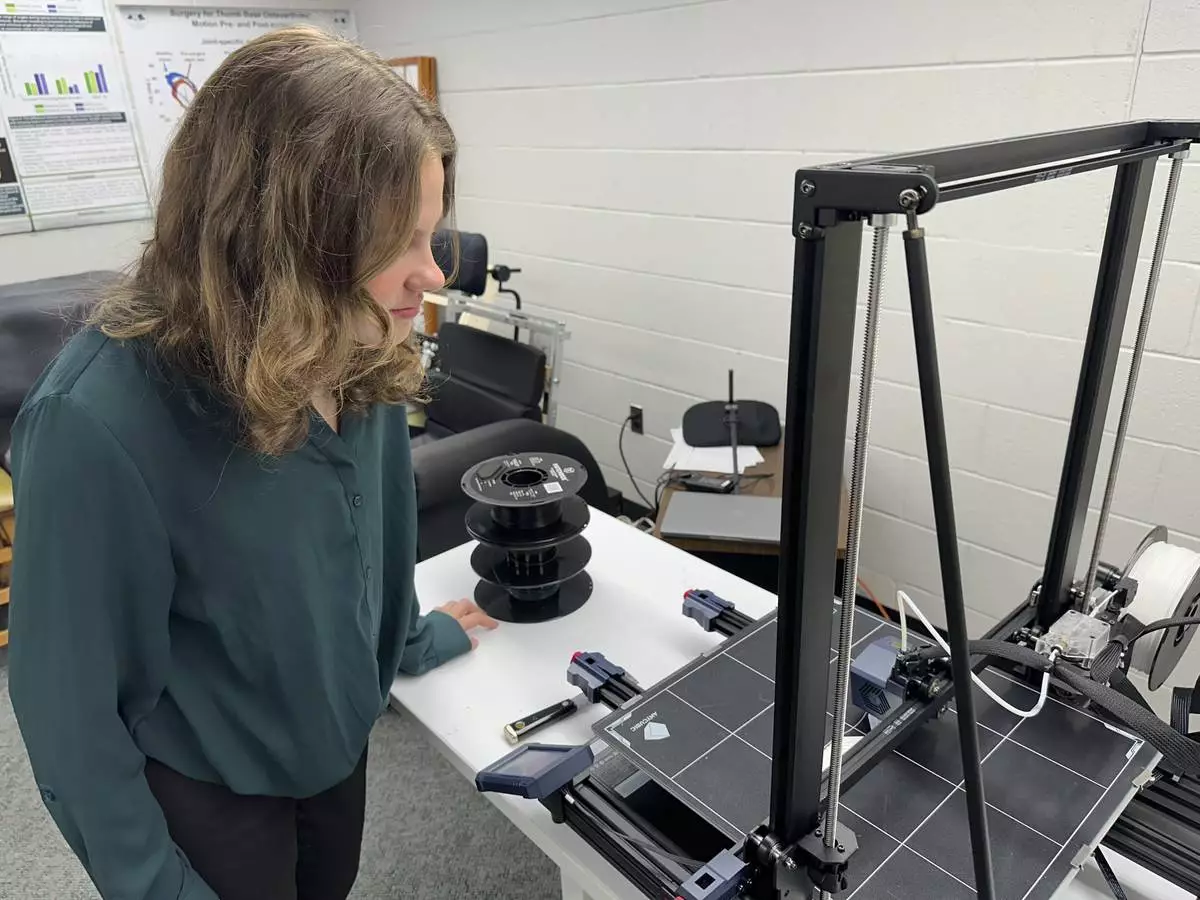

Bush and Rylie DuBois, a sophomore biosystems engineering major and undergraduate research assistant at the lab, set out to produce earhole inserts made from polylactic acid, a bio-based plastic, using a 3D printer. Part of the challenge was accounting for the earhole sizes and shapes that vary depending on helmet style.

Once the season got underway with a Friday night home game against Florida Atlantic on Aug. 30, the helmets of starting quarterback Aidan Chiles and linebacker Jordan Turner were outfitted with the inserts, which helped mitigate crowd noise.

DuBois attended the game, sitting in the student section.

“I felt such a strong sense of accomplishment and pride,” DuBois said. “And I told all my friends around me about how I designed what they were wearing on the field.”

All told, Bush and DuBois have produced around 180 sets of the inserts, a number that grew in part due to the variety of helmet designs and colors that are available to be worn by Spartan players any given Saturday. Plus, the engineering folks have been fine-tuning their design throughout the season.

Dozens of Bowl Subdivision programs are doing something similar. In many cases, they’re getting 3D-printed earhole covers from XO Armor Technologies, which provides on-site, on-demand 3D printing of athletic wearables.

The Auburn, Alabama-based company has donated its version of the earhole covers to the equipment managers of programs ranging from Georgia and Clemson to Boise State and Arizona State in the hope the schools would consider doing business with XO Armor in the future, said Jeff Klosterman, vice president of business development.

XO Armor first was approached by the Houston Texans at the end of last season about creating something to assist quarterback C.J. Stroud in better hearing play calls delivered to his helmet during road games. XO Armor worked on a solution and had completed one when it received another inquiry: Ohio State, which had heard Michigan State was moving forward with helmet inserts, wondered if XO Armor had anything in the works.

“We kind of just did this as a one-off favor to the Texans and honestly didn’t forecast it becoming our viral moment in college football,” Klosterman said. “We’ve now got about 60 teams across college football and the NFL wearing our sound-deadening earhole covers every weekend.”

The rules state that only one player for each team is permitted to be in communication with coaches while on the field. For the Spartans, it’s typically Chiles on offense and Turner on defense. Turner prefers to have an insert in both earholes, but Chiles has asked that the insert be used in only one on his helmet.

Chiles “likes to be able to feel like he has some sort of outward exposure,” Kolpacki said.

Exposure is something the sophomore signal-caller from Long Beach, California, had in away games against Michigan and Oregon this season. Michigan Stadium welcomed 110,000-plus fans for the Oct. 26 matchup between the in-state rivals. And while just under 60,000 packed Autzen Stadium in Eugene, Oregon, for the Ducks' 31-10 win over Michigan State three weeks earlier, it was plenty loud. “The Big Ten has some pretty impressive venues,” Kolpacki said.

“It can be just deafening,” he said. “That's what those fans are there for is to create havoc and make it difficult for coaches to get a play call off.”

Something that is a bit easier to handle thanks to Bush and her team. She called the inserts a “win-win-win" for everyone.

“It’s exciting for me to work with athletics and the football team," she said. "I think it’s really exciting for our students as well to take what they’ve learned and develop and design something and see it being used and executed.”

Get alerts on the latest AP Top 25 poll throughout the season. Sign up here. AP college football: https://apnews.com/hub/college-football and https://apnews.com/hub/ap-top-25-college-football-poll

A 3D printer creates helmet inserts at Michigan State University's Biomechanical Design Research Laboratory, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

A 3D printer creates helmet inserts at Michigan State University's Biomechanical Design Research Laboratory, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Rylie DuBois, a sophomore biosystems engineering major at Michigan State University, watches as a 3D printer creates helmet inserts at the school's Biomechanical Design Research Laboratory, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Rylie DuBois, a sophomore biosystems engineering major at Michigan State University, uses a computer-aided design program at the school's Biomechanical Design Research Laboratory, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Rylie DuBois, a sophomore biosystems engineering major at Michigan State University, uses a computer-aided design program at the school's Biomechanical Design Research Laboratory, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Andrew Kolpacki, Michigan State University's head football equipment manager, holds three helmet inserts created by a professor at the school's College of Engineering, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Andrew Kolpacki, Michigan State University's head football equipment manager, examines part of a coach-to-player communication system inside the school's football complex, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)

Andrew Kolpacki, Michigan State University's head football equipment manager, surveys players' helmets located on a table inside the school's football complex, Monday, Nov. 18, 2024, in East Lansing, Mich. (AP Photo/Mike Householder)