Various digital and automated technologies widely used in China's food industry chains and supply chains have significantly facilitated the development of foreign companies in China, including fast food giant McDonald's.

McDonald's made its debut at the ongoing second China International Supply Chain Expo (CISCE), which takes place in Beijing from Tuesday to Saturday.

The McDonald's exhibition booth at the expo is filled with fast food such as hamburgers and French fries. Every bite of the hamburger contains products and services from as many as 100 suppliers. For example, bread, lettuce, and cheese come from Beijing, sauce comes from north China's Hebei Province, and beef comes from as far away as Australia.

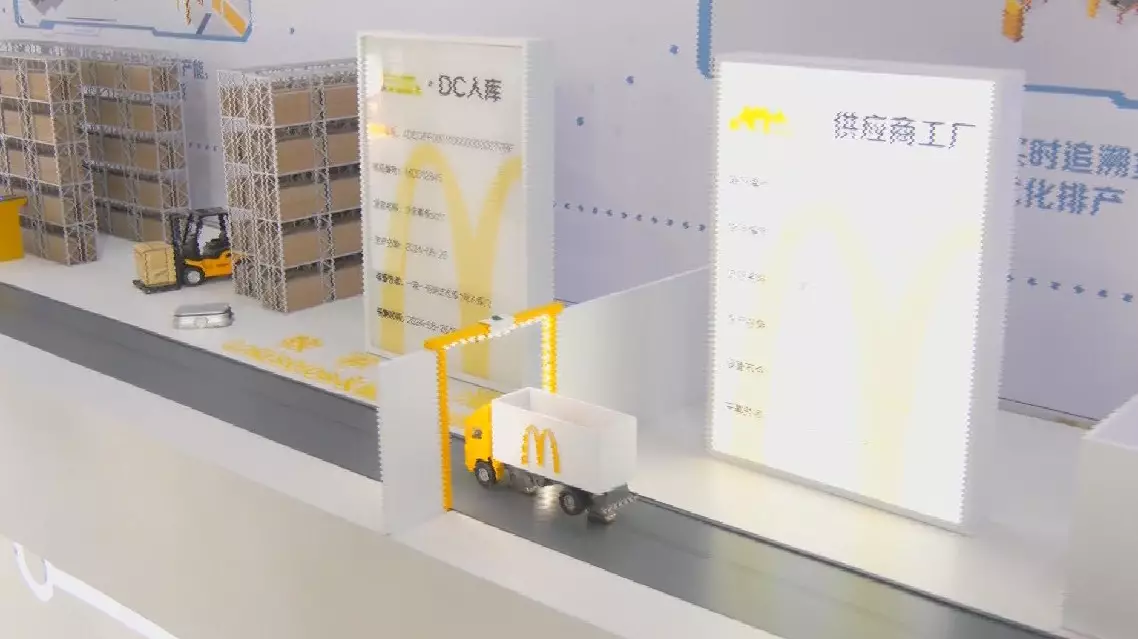

The "one box, one code" technology displayed by McDonald's at the expo has been rolled out across China and installed in more than 100 suppliers' factories. With the technology, every link in the production of any product can be traced back through a code on the shipping box. The technology aims to improve the efficiency and quality of supply chain data management. In addition, production and logistics can be allocated according to the restaurant's real-time inventory information to avoid food waste.

A smart industrial park in central China's Hubei Province was completed and put into operation in July this year. It is the first industrial cluster park for China's western fast food industry. The park was jointly built by McDonald's and four of its major suppliers, covering the entire industrial chain of food production, packaging, cold chain and distribution.

In the automated smart warehouse of the industrial park, goods delivered from different factories adopts the "one box, one code", which enables information exchange among factories, logistics and restaurants.

The equipment in the entire warehouse is basically running automatically. The logistics transport vehicle can automatically identify the QR code on the ground, deliver the goods to the warehouse, and carry out unmanned loading and unloading. In the sorting process, the robotic arms can identify the "digital ID card" on the boxes, and complete product matching according to the needs of different restaurants.

Intelligent management and automated processes like this have shortened the logistics time for goods entering the warehouse by 90 percent compared to before, which has not only improved efficiency but also reduced costs for McDonald's and other food companies alike.

The beef in McDonald's Angus beef burgers comes from ranches in Australia. In order to build a better reputation in the global supply chain, Australia has developed a meat standard evaluation mechanism for beef and mutton. The design of this evaluation mechanism is very diverse, based on more than 800,000 taste tests conducted by at least 100,000 consumers in 11 countries around the world.

As China's global supply chain continues to grow, Australian beef products are reaching more Chinese consumers. In order to better serve Chinese consumers, local farmers and purchasers have added labels to the packaging of beef products. Through any mobile phone that can read chips, people can access all the information about this product from the first day of production to every logistics link.

China's digital, automated supply chains benefit foreign food companies