China's CRRC rolling stock manufacturing company has strengthened its global presence by meeting over 80 percent of the industry's supply needs locally, powered by its robust smart supply chain and industrial clusters.

As the world's largest supplier of rail transit equipment with the most complete production lines and leading technologies, the CRRC collaborates with more than 2,000 companies on the supply chain for high-speed trains, which consist of 40,000 components in Zhuzhou, a city in south-central China's Hunan Province and the birthplace of China's electric locomotives.

At the CRRC's plant, production lines are operating at full capacity, focused on producing traction converters and network control systems for high-speed rail.

"Once we receive production demands, we plan scheduling based on the overall strategy. Now, with the supply chain collaboration platform, we share these demands with upstream suppliers, boosting supply efficiency and ensuring seamless information exchange for faster customer response," said Qiao Lin, deputy director of the Procurement Center at Zhuzhou CRRC Times Electric Company Limited.

Previously, communication with suppliers would rely on manual data collection, which was time-consuming and often inaccurate, leading to frequent production errors. Today, with a smarter, more agile supply chain, the process is much more efficient.

"With our smart supply chain, order details like specifications, quantities, and delivery dates are shared directly with suppliers in real time. They deliver materials on schedule, ensuring everything arrives before production starts. This streamlines operations and reduces overall inventory levels," said Zhang Fengfei, deputy director of the Operations Management Department at CRRC Zhuzhou Electric Company Limited.

Reducing inventory is crucial for businesses. Less storage space frees up room for new products, and production lines can use materials more efficiently. Finished products are quickly transported to the next stop -- a key advantage of industrial clusters.

Nearby, CRRC Electric also benefits from this system. The company produces customized traction motors and transformers for locomotives using a flexible production line.

Trucks are loaded and ready to roll to Zhuzhou Locomotive, their final stop before assembly.

"Any changes are updated in real time. Adjustments to the production schedule automatically trigger updates to delivery timelines, and suppliers respond accordingly. Their feedback is sent back instantly, helping our production team make decisions. This real-time coordination ensures seamless production and more accurate execution," said Qi Ran, associate director of Supply Chain at CRRC Zhuzhou Locomotive Company.

With its products reaching over six continents and more than 50 countries and regions, CRRC is bringing China's speed and expertise to the rest of the world.

CRRC strengthens global presence with smart supply chain

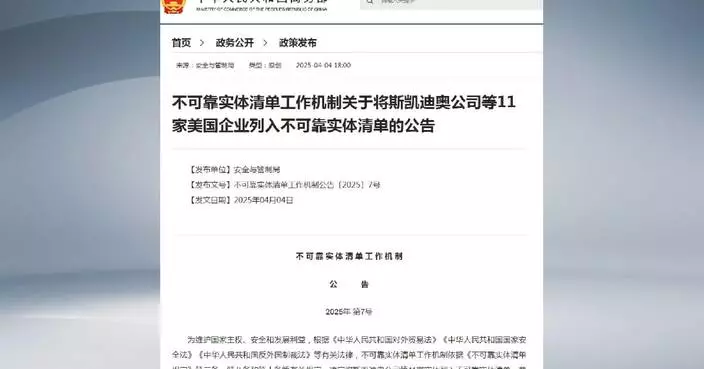

A deal to give the United States exclusive access to Ukraine's mineral resources has sparked contention among Ukrainian experts, who have described earlier drafts of the agreement as "unacceptable" and "colonial."

As the war between Ukraine and Russia is showing signs of winding down, another battle is quietly unfolding beneath Ukrainian soil, with competitors eying Ukraine's vast reserves of critical minerals.

The United States and Ukraine have signed an agreement to establish the U.S.-Ukraine Reconstruction Investment Fund, the U.S. Treasury Department announced on Wednesday.

For some, the minerals deal with the United States offers a lifeline for Kiev's war-torn economy. For others, it signals the quiet start of a resource takeover, raising concerns about what Ukraine may be giving away in exchange for support.

Ukraine is rich in critical resources such as graphite, lithium, and titanium. All these are vital to electric vehicles, the aerospace industry, and the high-tech supply chain.

At a graphite quarry roughly 400 km south from Kiev, capital of Ukraine, the roads give way to deep ruts and scattered debris, which means the mine site falls short of normal operation in wartime.

According to Ukraine's geological survey, the country holds 22 of the 50 strategic materials identified by the U.S. as critical.

As the global race for these resources intensifies, Washington is eager to secure reliable access. Ukraine, desperate for investment for reconstruction, has opened its doors. However, according to experts, the negotiations have been tense.

"When we had the first draft of this agreement, it was absolutely awful, absolutely unacceptable for Ukraine. It was also like a colonial agreement," said Volodymyr Landa, senior economist at the Center of Economic Strategy of Ukraine.

The country's mining sector is in dire need of foreign capital. At one of Ukraine's largest graphite deposits, infrastructure is minimal, with a few dogs, a guard, and an elderly tractor driver.

A Lviv-based mine owner said water pipes freeze over in winter, bringing operations to a halt. More importantly, the war has drained both labor and funding.

"If the Ukrainian government presents it for free, for 50 years with free rent, our resources will lose from that," said Ostap Kostiuk, CEO of Zavallivskyi Graphite, located in the Kirovohrad region.

Following a tense and reportedly humiliating visit to Washington in March, Ukrainian President Volodymyr Zelensky appears to have softened his stance on a minerals deal he once said he would never sign. The move has triggered public outcry at home.

"Now they (the U.S.) say 'give me money, no, lithium' for the guarantees. It's not fair, I think," said a local resident.

"I definitely started to respect America less. He (Trump) is not interested in Ukraine actually ending the war," another added.

This graphite deposit represents only a fraction of Ukraine's untapped potential. An estimated 30 percent of its critical minerals have already been extracted. The other 70 percent, still buried across vast swathes of the country, is what many believe Washington is ultimately eying.

"Please do everything to make this peace closer to us, closer to people, closer to Ukrainians. Because every day, every hour, every minute, it costs our Ukrainian nation one to five Ukrainian best guys' lives," said Kostiuk.

In the view of Professor Valeriy Pekar, a business scholar in Kyiv and Lviv, the Trump administration is not actually interested in securing peace for Ukraine.

"To take control of our resources, it is necessary to end the war. The American leadership declares themselves great peacemakers, but what they really do is not peacemaking. It's war mongering," he said.

US interest in Ukraine's critical minerals draws public backlash