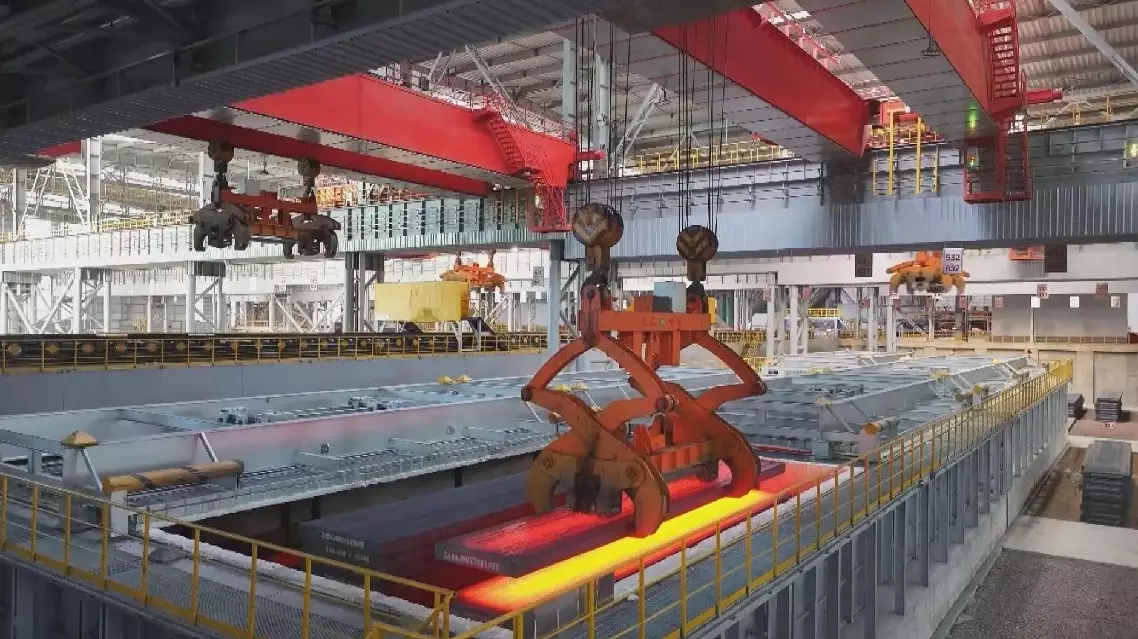

North China's Inner Mongolia Autonomous Region, one of the country's major coal production areas, has introduced intelligent systems at freight railway stations to improve coal transportation efficiency and ensure safe operation of heavy trains with a transport capacity of 10,000 tonnes.

Over 60 percent of the coal from 73 coal mines in Ordos City are loaded onto freight trains at the Hantaichuan North Railway Station coal logistic park, where the coal is then transported to cities across the country.

Since November, the average daily transport of coal in the logistics park has reached more than 60,000 tonnes, which was achieved with the help of an intelligent loading system.

The system can automatically identify the numbers and loading amounts of railcars when a train moves along the loading line. Once the system detects a railcar, the coal outlet above quickly opens and pours down coal into the car.

As the train moves forward, multiple processes, such as coal loading, antifreeze spraying, surface leveling, and dust suppression are conducted simultaneously. It takes only about a minute to fill a railcar with coal.

"Since the introduction of this intelligent loading system, it takes only about two hours to load a 10,000-tonne train, saving two-thirds of the time," said Liu Yansheng, deputy manager of the Hantaichuan North Business Department of Baotou Railway Logistics Center of China Railway Hohhot Bureau Group.

In addition to loading, the system can also automatically completes tasks such as batching, railcar dynamic tracking and unloading, enabling fully automated and unmanned operation in the entire process of coal transporting. It makes the entire process precise and efficient, avoiding mistakes that may be caused by human error.

"There is a buffer bin above, where coal is stored in advance. The precise coal batching for the quantity bin is then controlled by adjusting the opening of the A, B, C, D four gates at the bottom of the buffer bin. The loading station is connected to the coal storage shed by a conveyor belt system. The storage, loading, unloading and dispatching processes are all completed in a fully enclosed belt corridor," said Ruan Jinsheng, head of the loading tower of the logistics park.

Currently, 73 percent of the 37 coal loading bases in the central and western regions of Inner Mongolia have already implemented intelligent loading systems. Since October, the daily average coal transportation amount from railway stations in central and western Inner Mongolia has reached 594,900 tonnes, up 22.51 percent from the same period of last year. On average, 35 trains with a transportation capacity of 10,000 tonnes departed from the region for ports every day.

Hohhot South Railway Station is another key hub for the west-to-east coal transportation in Inner Mongolia, as well as a necessary transit point for 10,000-tonne trains.

As a transit point for 10,000-tonne trains, the station covers approximately 450,000 square meters, about the size of 63 football fields. Freight trains make stopover at the station mainly for two tasks.

The first one is to replace the standard locomotive with two heavy-duty locomotives, as such locomotives can smoothly pull the 10,000-tonne train up the uphill sections on its route heading east to the Caofeidian Port.

Another reason for the stopover is to attach a safety protection device to the rear of the train, which enables the train driver to monitor whether the train is complete and if the operating conditions are normal.

Currently, the station handles more than 240 incoming and departing trains, with a daily coal transportation volume of around 300,000 tonnes.

In order to improve operational efficiency and reduce dwelling time, the station has increased manpower at key stages to speed up the turnover of the train flow. Now, the time required for the entire process of transit operation at the station has been shortened from two hours to 50 minutes.

Intelligent systems improve coal transportation efficiency in Inner Mongolia