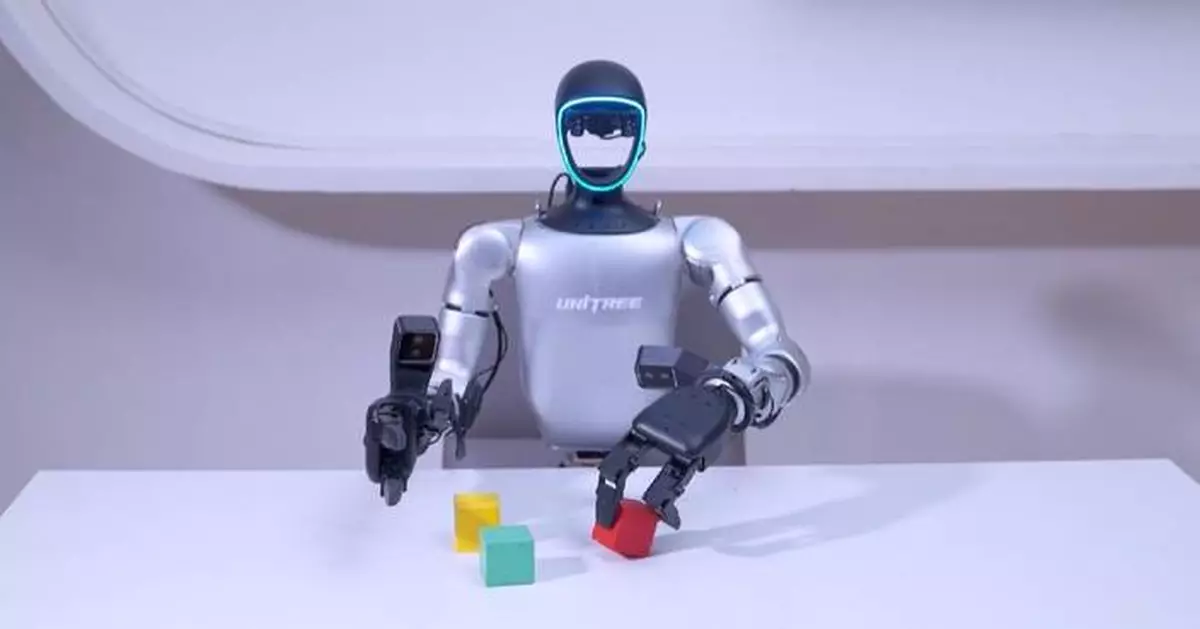

As the global race to develop humanoid robots is heating up, China has recently scored significant advancements in the industry, with mass production of embodied artificial intelligence-powered robots already realized.

A tech firm based in Shanghai have already begun mass production of humanoid robots, with nearly 1,000 units of humanoid robots produced in 2024.

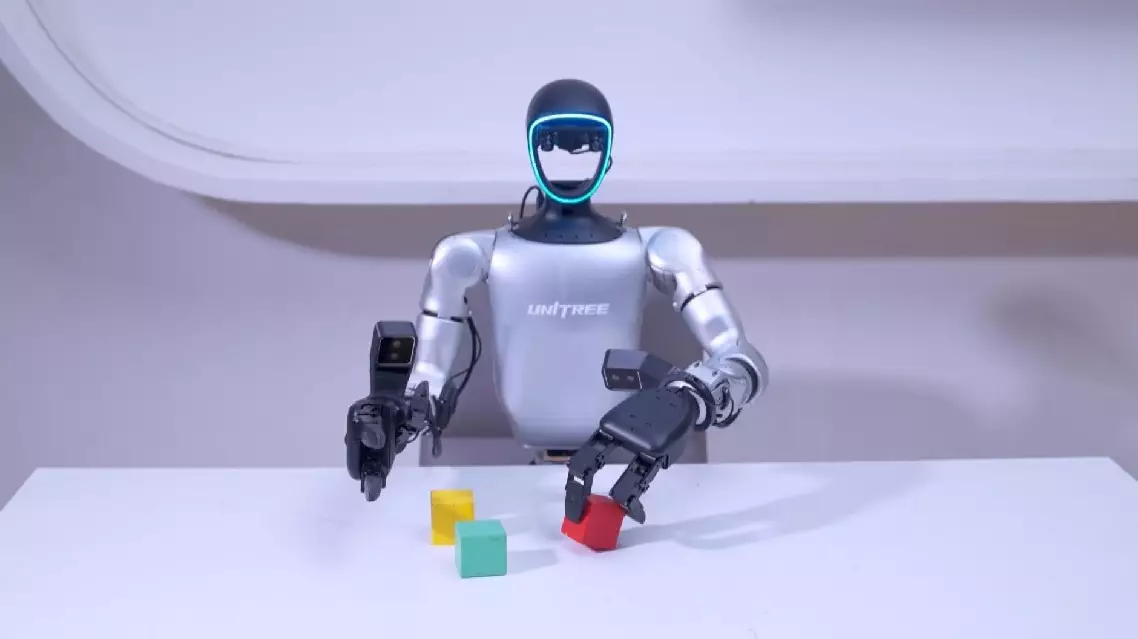

The humanoid robot produced by the company can be regarded as a general-purpose platform with certain AI capabilities, and on this basis, customers, spanning various sectors such as scientific research, manufacturing, and business affairs, can carry out secondary development in accordance with their needs, according to the company's production leader.

It took only less than nine months for the company to advance from setting up the production line to the mass production.

"It's estimated to have a production capacity of nearly 1,000 units this year (2024). And there are many orders, so our production line now is almost working at full capacity. Next year (2025), we expect to reach a production capacity of thousands of units," said Zhang Shaozheng, general manager at the manufacturing department of a humanoid robot factory in Shanghai.

Prior to the whole machine test, the robots have to go through multiple stages of sub-testing. For instance, the squat test for the single leg of a robot needs to be carried out more than 2,000 times before the assembly.

"The testing load is 30 kilograms, and we need to check its support for the upper limbs. If there is a problem with the legs, the robot may limp or fall while walking," said Huang Jiashun, test engineer of the humanoid robot factory in Shanghai.

With more than 40 degrees of freedom, the robot is capable of realizing versatile movements.

In particular, the upstream precision machining of many key components has overlapped with that of the domestic new energy vehicle industry.

"Some precision components like electric drive and reduction gearbox [in the new energy vehicle industry] can be easily applied to the robot industry, with most of them realizing a high localization rate. Because of the maturity of the entire upstream supply chain, we have been able to build such a robot in such a short period of time," said Zhang.

In addition, the tech firm has also set up a data collection factory for embodied AI, which describes the integration of a robot's machine learning, computer vision, and language technologies.

At the factory of more than 2,000 square meters, a string of working scenarios, such as kitchen and supermarket, have been set up to conduct data collection for hundreds of robots.

A major feature of embodied intelligence is to allow humanoid robots to constantly learn human actions by interacting with the physical world through its limbs with the help of large AI models.

The data collectors at the factory guide the robots to perform various actions, after which the collected data will be transmitted to the cloud for massive virtual training. The general-purpose model capabilities formed through generalization learning can be installed on every robot in the future.

The head of the tech firm said that their products will be endowed with more capabilities like touch and different forms including bipedal and wheeled robots in the near future, while costs will be reduced at the same time.

The global humanoid robot industry was booming in 2024, and many innovation centers for humanoid robots were established across China, with some products stepping into the incipient stage of commercialization, according to Wang Hao, head of the Industrial Policy Institute of the China Center for Information Industry Development (CCID) under the Ministry of Industry and Information Technology.

"Humanoid robots will certainly develop faster in 2025, but there are still some breakthroughs to be made in both software and hardware before they can move quickly and autonomously like humans and perceive people's intentions well. We hope that humanoid robot products can continue to mature and enter thousands of households in the future," Wang said.

China steps into era of mass production of humanoid robots