Disaster relief efforts are in full swing in southwest China's Xizang Autonomous Region following a 6.8-magnitude earthquake, with hundreds of personnel installing prefabricated homes to relocate affected residents.

The quake jolted Dingri County of Xigaze City on Tuesday morning, with at least 126 people confirmed to have lost their lives and 188 others injured, and over 3,600 homes collapsed.

As of 17:00 Thursday, the Ministry of Emergency Management had mobilized emergency rescue teams specializing in engineering, safety production and emergency power supply.

A total of 84 teams have been deployed, comprising 1,586 people, with 1,019 sets of equipment and three helicopters.

So far, over 160 damaged houses have been checked and 500 households have received emergency aid, totaling more than 2,600 people.

These teams have also helped install over 100 prefabricated houses and delivered more than 61,000 emergency relief items.

Meanwhile, materials such as mobile homes have started arriving in the earthquake-affected areas.

In Lhaze County, the installation of the first batch of prefabricated homes is underway.

On Thursday, at a vacant site in front of Lhaze High School, excavators were leveling the ground in preparation for the construction of these prefabricated homes.

By 19:00 Thursday, half of the ground was leveled and 400 sets of mobile homes had been delivered to the construction site.

Work on the water and power supply for these homes was also progressing.

"Due to the weather conditions, strong winds, the hoisting work is risky. But we'll try our best to speed up the progress while ensuring the safety," said Jiang Lei, site manager of the Lhaze relocation project.

Relief efforts in full swing in quake-hit Xizang

Relief efforts in full swing in quake-hit Xizang

Relief efforts in full swing in quake-hit Xizang

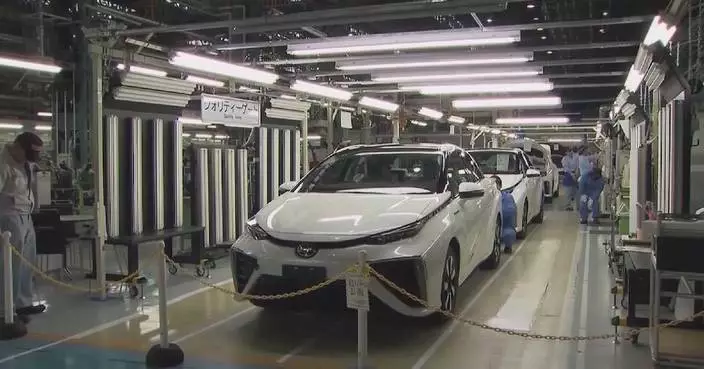

In spite of favorable policies introduced to support exporters to pivot to the domestic market, export companies are also actively taking measures to boost innovation and even increase their market shares as a way out amid tariff disputes with the U.S.

Zhejiang Taida Miniature Electrical Machinery Co., Ltd. located in Huzhou City, east China's Zhejiang Province is the very example of adopting innovation to navigate through the hard times.

Despite the impact of the U.S. "reciprocal tariffs," the company has not only maintained production but also expanded its workforce.

According to the head of the company, their fans and heat dissipation products are widely used in electrical appliances, computers, and more. These small fans have been in great demand thanks to the company's self-developed fan chips.

"Previously, our motors were traditional, using more materials. After incorporating chips, the noise is reduced, and the airflow is much stronger, which is essential for equipment cooling. Our new developments, including this one, are all focused on ventilation and heat dissipation," said Qiu Rongquan, chairman of the company.

With the core technological advantage of chip-based ventilation and heat dissipation, the fans can operate efficiently in different countries and under various voltage conditions.

As a result, the company's products are not only exported to Europe but have also expanded into emerging markets like the Middle East, with product profit margins increasing by 20 percent.

Moreover, with the rapid development of the new energy industry in recent years, the company has set up an expert studio and relocated a national laboratory into their office building.

They have developed specialized heat dissipation products for new energy charging stations and formed production partnerships with leading domestic companies in the industry.

Being innovative and building internal capabilities have become the shared consensus for foreign trade companies undergoing transformation.

Dakang Holding Group Co., Ltd., a home furnishings company, started with the production of just chairs, but today, it offers over 1,000 product styles, with annual R&D investment exceeding 20 million yuan (about 2.77 million U.S. dollars).

The group has also intensified its collaborations with various designers. Recently, it seized the opportunity presented by the trade-in policy, enhancing its efforts to develop new products so as to attract more customers.

As a result, although its production for U.S. export was suspended recently, the workers have remained busy and worked nonstop for domestic market driven by new product innovations.

"Currently, our domestic market has been expanding steadily in recent years since we've explored high-end customization and engineering customization, with an annual growth rate of around 20 percent," said Hu Yueqiang, director of the group's High-end Custom Furniture Division.

With the development of its domestic market, the group has also gradually increased its factories.

The group built two factories in 2015 that were mainly for serving foreign trade. In 2017, a third factory was built and later shifted to produce for the domestic market. In 2024, the group again built three more factories, totaling 80,000 square meters.

Innovation helps enterprises expand domestic sales amid tariff disputes