JUAREZ, Mexico--(BUSINESS WIRE)--Apr 16, 2025--

Due to the increasing demand for high-quality custom metal components, Komaspec, a Canadian-owned contract manufacturer, has added its newest manufacturing facility in Mexico, adding 20,000 square feet to its global production network and the option to price and produce parts in both Mexico and China. This expansion is a key milestone in serving the North American market with reduced lead times and enhanced manufacturing efficiency.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250416291002/en/

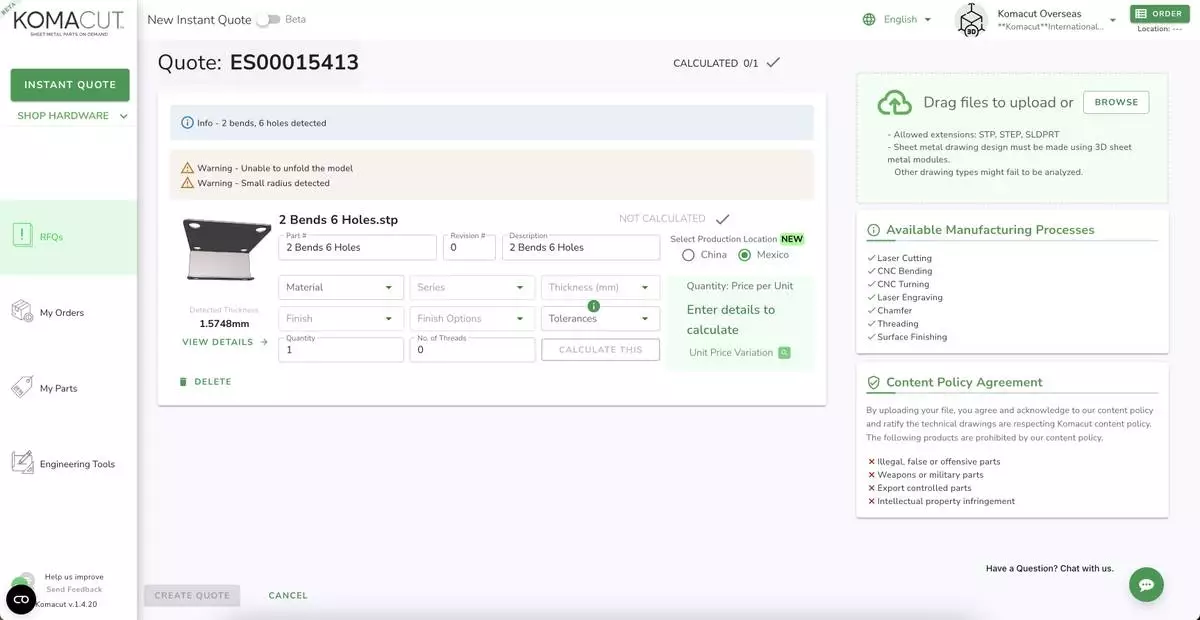

The custom metal parts produced in this facility are available exclusively through Komacut.com, Komaspec’s on-demand digital platform for sheet metal fabrication. Customers can access instant online quotations, seamless ordering, and fast delivery for high-precision metal parts directly from the Mexico-based factory.

Located in a free trade zone, the facility is equipped with state-of-the-art manufacturing technology to support a range of custom sheet metal fabrication capabilities, including:

By manufacturing in Mexico, Komaspec significantly reduces shipping times for customers in the United States, Canada, and Latin America.

Through Komacut.com, businesses can instantly quote, order, and receive custom metal parts with a seamless digital experience. The platform provides instant, transparent pricing, DFM (Design for Manufacturing) feedback, and fast production, ensuring efficiency, quality, and scalability for OEMs, small businesses and big brands.

In 2024, Komacut produced hundreds of thousands of high-precision parts for customers worldwide. As part of its long-term strategy, the company continues to invest in automation, digital manufacturing, and vertically integrated operations, reinforcing its commitment to providing premium-quality custom parts at scale.

About Komaspec & Komacut

Founded in 2005, Komaspec is a full-service contract manufacturer, specializing in custom sheet metal fabrication, electro-mechanical assemblies, and turnkey production solutions. With facilities in China and Mexico, Komaspec enables businesses to innovate faster through advanced manufacturing technologies and digital ordering capabilities.

Komacut is Komaspec’s business-facing, on-demand metal fabrication platform, allowing customers to instantly quote and order custom sheet metal and machined parts online. With fast production, transparent pricing, and global logistics support, Komacut streamlines the manufacturing process from design to delivery.

For more information, visit www.komacut.com.

Komacut’s instant quoting platform, allowing users to choose between production in Mexico or China for maximum flexibility.

Automated laser cutting system and material storage tower in Komacut’s Mexico facility, designed for high-volume precision manufacturing.

Inside Komacut’s Mexico facility, featuring advanced machinery and optimized production zones for efficient custom metal part manufacturing.