LONDON--(BUSINESS WIRE)--Apr 24, 2025--

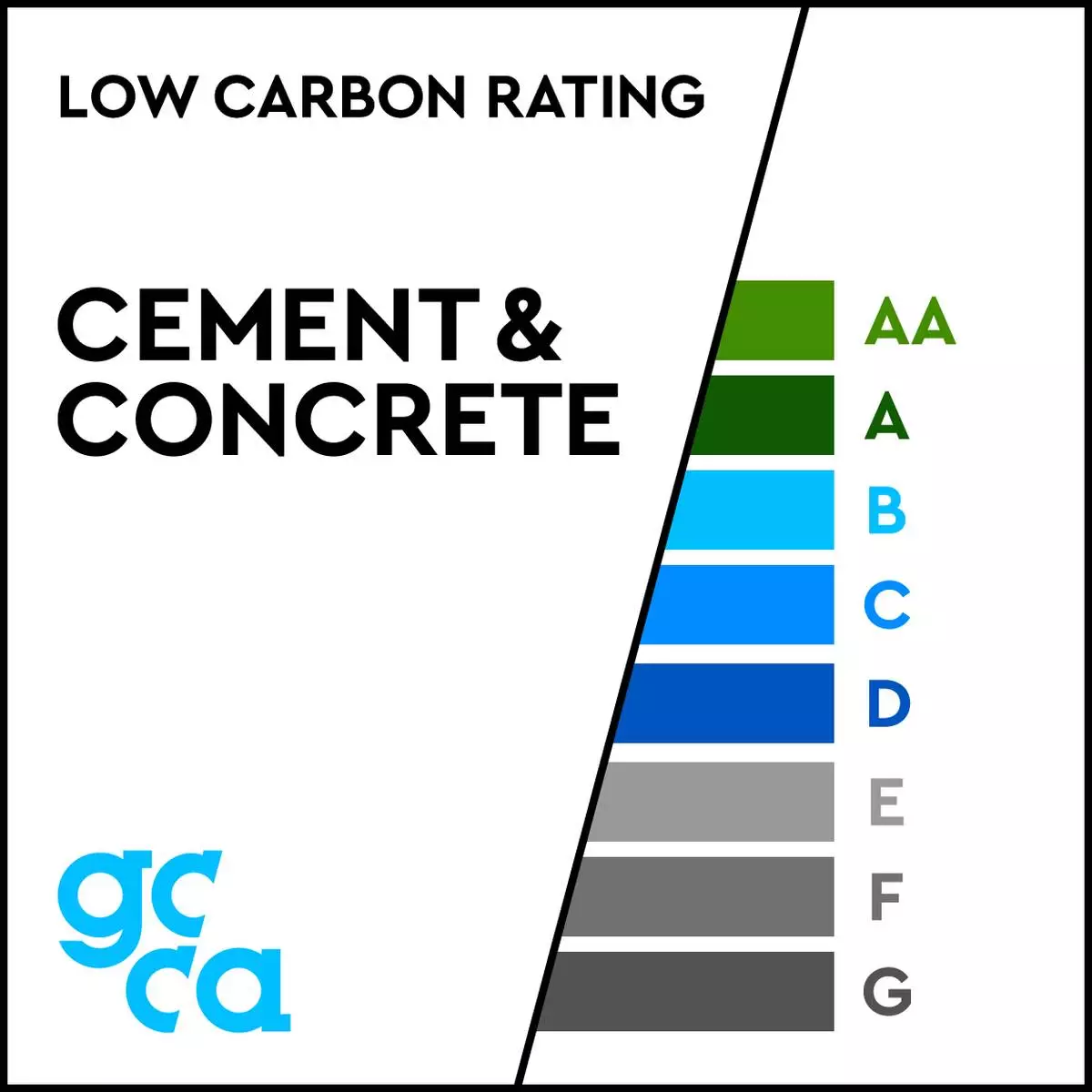

The Global Cement and Concrete Association (GCCA) announces the launch of Low Carbon Ratings (LCR) for Cement and Concrete - a first-of-its-kind transparent global rating system that will enable cement and concrete to be identified based on their carbon footprints. The ratings system is designed to help customers prioritise sustainability when selecting construction materials by using a clear and intuitive AA to G scale.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250424485662/en/

Inspired by well-known appraising schemes such as the EU’s Energy Performance Certificates and the US Home Energy Rating System, the LCR offers a simple, transparent, and adaptable tool that helps builders, architects, governments, planners, and consumers everywhere in the world to make more informed and sustainable choices.

Thomas Guillot, Chief Executive of the GCCA, said: “Cement and concrete are the foundations of modern life - from the buildings we live and work in, to the roads we travel, and the infrastructure that supports clean water and green energy. As global demand for sustainable construction grows, the need for greater transparency around the carbon footprint of construction materials is more critical than ever.

“Our Low Carbon Ratings system supports more sustainable procurement practices and will empower the entire value chain to accelerate decarbonisation.”

The ratings system is designed to be easily recognisable – with a simple visual graphic that clearly indicates a product’s rating. The carbon rating system for cement and concrete provides consistency and comparability. Countries can adopt the global ratings as they are, or adapt them if local carbon accounting differs from global norms.

Riccardo Savigliano, Chief, Energy Systems and Decarbonization Unit, UNIDO said: “This is a huge step forward towards harmonizing global definitions for low emission cement and concrete in the support of decarbonization.”

With notable construction projects already demonstrating the use of lower carbon cement and concrete, the industry is making important progress. The launch of this global rating system marks another milestone on the road to greater sustainability.

Marlène Dance – Decarbonisation & Sustainable Design Expert, Bouygues Bâtiment International said:“We believe a globally consistent carbon rating system—adopted by all countries and used by all concrete suppliers—would be a game changer.

“We see great value in a simple, user-friendly tool, tailored for construction teams. It will help empower our site crews to better understand and manage the carbon footprint of the concrete they use.”

Mr Guillot added: “With this rating system in place, governments, policymakers and the private sector can now prioritise lower carbon cement and concrete in the procurement process which will in turn further stimulate the industry’s focus on decarbonising these essential building materials.”

Note to editors

The rating system is designed to be used with Environmental Product Declarations (EPDs) - which by definition are third party verified.

The rating system uses numerical definitions in units of embodied carbon dioxide equivalent per tonne for cement and per cubic metre of concrete product (ECO2e /m3), also referred to as Global Warming Potential (GWP), as calculated according to Environmental Product Declarations (EPDs) standards. These product definitions for “low carbon” and “near zero” carbon emissions were inspired from cement production definitions by the International Energy Agency and the GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete.

The GCCA cement rating system can be adopted and applied in countries. Germany already provides a working example. The German Federal Ministry for Economic Affairs and Climate Action and VDZ (German Cement Association) developed a scheme that is fully aligned with the GCCA system and this is already implemented.

The GCCA worked with the Clean Energy Ministerial Industrial Deep Decarbonisation Initiative (IDDI) and stakeholders to create a set of globally applicable definitions for concrete. These are ready to use in the vast majority of countries. If a country has a different practice for product carbon accounting, then adaptation of the ratings can be done. This has already been completed in the UK.

The GCCA cement and concrete ratings can be used with national and local baselines and targets to support low carbon procurement.

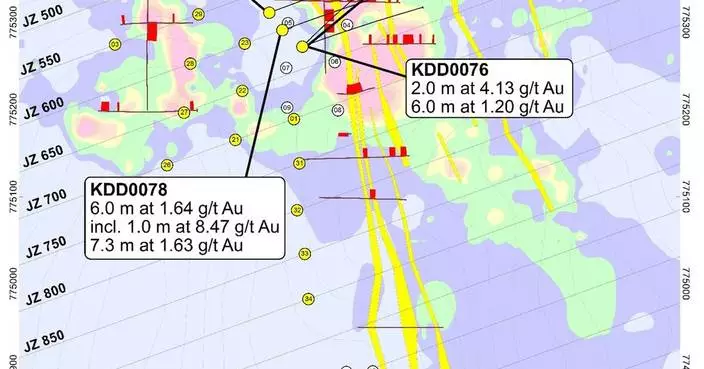

GCCA Low Carbon Ratings Grading Scale

GCCA Low Carbon Ratings for Cement and Concrete