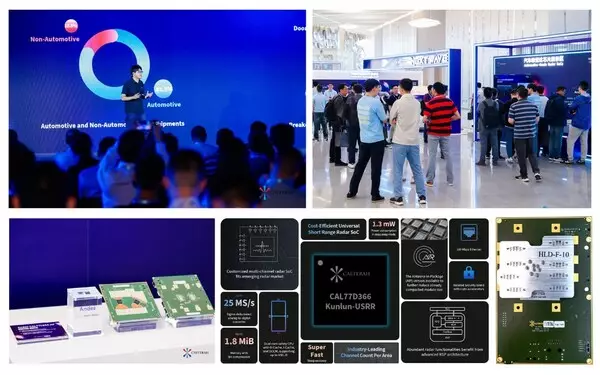

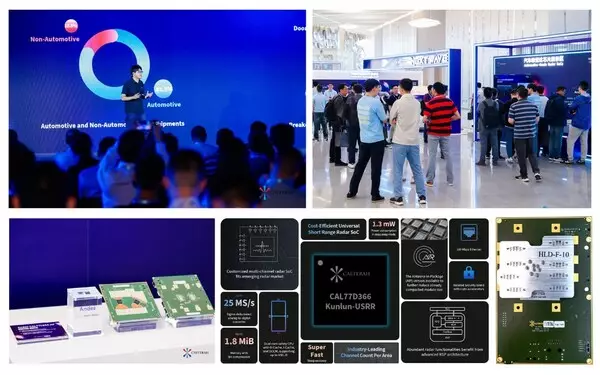

SHANGHAI, July 5, 2024 /PRNewswire/ -- At Calterah Day 2024 on June 6 in Shanghai, Calterah revealed its 2-chip cascading imaging radar solution using Andes SoCs, two 6T6R mm-wave radar SoC series—Kunlun-USRR and Lancang USRR, along with an innovative package technology—ROP®. Calterah also invited experts in the mm-wave tech field and ecosystem partners to explore how mm-wave radar can leverage cutting-edge technologies to address swiftly changing demands for radar.

Surmounting "Andes" and Defining New Paradigm for R&D of Imaging Radar

At the event, Calterah unveiled a 2-chip cascading imaging radar solution using Andes SoCs, indicating the chip named after the largest mountain range in South America—Andes, will enter mass production soon.

Based on the 22 nm CMOS process, the Andes SoC integrates an RF module with industry-leading performances and boasts the unique architecture of a quad-core CPU with a DSP and a proprietary Radar Signal Processor (RSP), which offers ultra-strong computing power for exceptional and flexible signal processing.

Owing to the Flex-Cascading® function of Andes, Calterah redefines the R&D paradigm of imaging radar. By cascading two Andes SoCs through Chip-to-Chip interfaces, customers can readily realize an imaging radar system, which scales up chip resources, simplifies the hardware architecture, optimizes the BOM, and allows software reuse.

Calterah 2-Chip Cascading Imaging Radar Solution supports up to 64 MIMO channels, provides a 320-meter maximum detection range with a 1.5° azimuth separation, a 3° elevation separation, and outputs 2048 point targets per frame. Calterah also demonstrated the field test results of the imaging radar solution, which highlighted its highly competitive detection capabilities in maximum detection range, separation of strong and weak targets in complex traffic scenarios, hidden target detection, and detection at intersections, on highways, etc. Calterah announced this solution would be brought to market very soon this June.

Scaling "Kunlun" and Pushing Frontiers of Vehicle Perception

Calterah Kunlun automotive mm-wave radar SoC platform came into being to primarily meet the differentiated requirements on radar put by emerging applications, such as automatic obstacle avoidance doors, passenger monitoring, and child presence detection, including lower power consumption, smaller size, and better angular and spatial resolution.

Calterah unveiled the 77 GHz Kunlun-USRR and 60 GHz Lancang-USRR SoC series, both developed on the Kunlun platform. USRR stands for Universal Short Range Radar, meaning these multi-channel SoCs are optimized and tailored to the needs of universal emerging radar applications.

Calterah Kunlun-USRR and Lancang-USRR SoCs have 6T6R, offering stronger angular performance. Each integrates a flexible and powerful RSP allowing customized signal processing flows. Different power modes ensure the ultra-low power consumption of short-range radar. Moreover, the antenna-in-package (AiP) version achieves a remarkably small package size of 13 mm × 16 mm, facilitating radar installation for emerging applications and expanding vehicle perception from ADAS to the interior and exterior of vehicles.

Samples of Calterah's Kunlun-USRR and Lancang-USRR SoCs are expected to be available in Q4, 2024.

ROP®â€”Optimal Chip Solution for Waveguide Antenna Systems

Calterah also revealed a cutting-edge mm-wave package technology—Radiator on Package (ROP®), which employs radiators to transmit signals to a waveguide antenna system and thus greatly reduces antenna feedline loss and improves channel isolation, better meeting the radar requirements of longer detection ranges and wider FOVs. Calterah ROP® package technology will be applied in the Alps-Pro and Andes SoC series.

As of Q1 in 2024, Calterah's accumulative chip shipments have exceeded 8 million units, and counting. For 2024, Calterah expects to ship over 6 million chips. This significant growth will breathe new life into the global mm-wave radar chip market.

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

Calterah Day 2024: Targeting 10 Billion Global Millimeter-Wave Radar Market, Calterah Aspires to Reach New Heights in Chip Technologies

CAMBRIDGE, Mass., July 8, 2024 /PRNewswire/ -- Today Athinia® announced a collaboration with ASNA to combine unprecedented data sharing and traceability to improve critical semiconductor component and subcomponent innovation. In today's fiercely competitive semiconductor landscape, the quality and reliability of components and subcomponents are paramount for achieving superior yield rates and minimizing defects during manufacturing.

ASNA, a pioneering force in the semiconductor manufacturing components segment, has joined forces with Athinia, the secure data and analytics platform for the semiconductor industry, to introduce a revolutionary concept aimed at tracking previously untraceable parts through the entire life cycle of the parts. This innovative initiative is confirming the significance of traceability and analytics, for consumable parts, in boosting yield and reducing defectivity within fabrication processes.

Athinia plays a pivotal role in this endeavor by enabling traceability, comprehensive data analytics and multi-party data sharing to provide a comprehensive understanding for each part's performance on yield in the manufacturing process. As a result, ASNA can see a full view of how to improve parts, delivering a lower cost of ownership with better fab performance to their customers.

"As we continue to engage more stakeholders across the semiconductor ecosystem, we can leverage the sharing of data, including data related to the subcomponents used in equipment which results in manufacturing improvements for device makers in their fabs. We are working together with ASNA and device makers to track parts that significantly impact performance and defectivity which were previously untraceable," said Laura Matz, CEO of Athinia and Chief Science and Technology Officer of Merck.

"Together with ASNA, we are pioneering an industry-leading concept to allow tracking of seals that will provide the industry with valuable insights and potentially enhance overall performance and quality."

ASNA's strategic deployment of Athinia extends beyond traditional manufacturing paradigms. ASNA develops innovative solutions that optimize the interplay between components, subcomponents, and overall equipment and wafer performance metrics by establishing the genealogy of parts traceability in the collaboration. This allows for the harnessing of advanced analytics and machine learning capabilities combined with on-wafer data. This proactive approach boosts understanding of critical components to yield, and closed-loop failure analysis elevates product reliability and market competitiveness.

"Components and subcomponent are pivotal in semiconductor manufacturing," stated Dalia Vernikovsky, CEO at ASNA. "Athinia empowers our engineers with insights and predictive analytics. We now have a normalized understanding of how our parts perform at our customers, allowing us to optimize processes, preempt potential issues, and ultimately make better performing products."

"Our commitment to excellence in components and subcomponent parts underscores ASNA's dedication to pushing technological boundaries," added Dalia Vernikovsky. "Through Athinia, we are poised to meet the evolving demands of global semiconductor markets with unmatched precision and agility."

About Athinia Technologies LLC

Athinia® provides a data analytics platform that brings manufacturers and materials and equipment suppliers together to share, aggregate, and analyze data to unlock efficiencies and time to market, while improving quality, supply chain, and sustainability – all without taking ownership of data. Athinia® is a partnership between Merck (DAX:MKGAF), and Palantir Technologies Inc. (NYSE:PLTR). Athinia® is headquartered in Cambridge, MA, USA, and operates independently from the Electronics business of Merck. More information can be found at www.athinia.com.

About ASNA:

ASNA is a leading innovator in semiconductor manufacturing, specializing in sealing, gaskets and component expertise. ASNA's reputation continues to be built on efforts to focus on world-class sealing solutions as well as traceability to mitigate defects that cause yield loss and manufacturing downtime. With a dedication to precision engineering and leveraging Athinia for data-driven insights, ASNA continues to shape the future of semiconductor technologies worldwide. Please visit www.asnaglobal.com for more information.

Press contacts:

** The press release content is from PR Newswire. Bastille Post is not involved in its creation. **

ASNA and Athinia® collaborate to boost semiconductor manufacturing yields through improved data sharing and traceability of subcomponent parts

ASNA and Athinia® collaborate to boost semiconductor manufacturing yields through improved data sharing and traceability of subcomponent parts