The super-sized LNG storage base in south China's Guangdong Province has made several breakthroughs in its design and construction, as the second phase of the base was completed on Friday.

Located in Zhuhai City, the second phase of the base named Jinwan "Green Energy Port" consists of five large liquefied natural gas (LNG) storage tanks with the world's largest single tank capacity of 270, 000 cubic meters.

The Jinwan "Green Energy Port" project is one of the LNG storage tank projects with the most complex geological conditions and the most difficult seismic design in China.

"Due to the large bedrock slope angle, among all the 2,030 piles built for the five storage tanks in the second phase of the Jinwan 'Green Energy Port' project, the longest is 70.6 meters and the shortest is 5 meters, representing the greatest variation in size among domestic storage tanks," said Han Xiaokang, a project manager of the second phase of Jinwan "Green Energy Port" project.

To overcome the limitations of tank capacity and enhance the safety and stability of storage tanks in multiple extreme conditions, engineering technicians have innovatively developed a fully autonomous technology system for the 270,000-cubic-meter LNG storage tanks, successfully overcoming the technical challenges such as structural stability analysis and seismic isolation designing.

"Each storage tank has more than 400 customized seismic isolation rubber supports at its base, creating a seismic isolation layer. When an earthquake occurs, the vibration energy from the lower foundation is first transmitted to the seismic isolation rubber supports. Through the deformation of the rubber under stress, most of the earthquake's energy is buffered and reduced, effectively preventing the transmission of seismic energy to the upper storage tank structure," said Huang Huan, a technical director of the second phase of Jinwan "Green Energy Port" project.

According to Huang, the engineering technicians have also independently developed a pile foundation technology, effectively reducing the probability of local damage and instability, with the average load difference on the pile foundation decreasing by 83 percent.

China's super-sized LNG storage base makes breakthroughs in design, construction

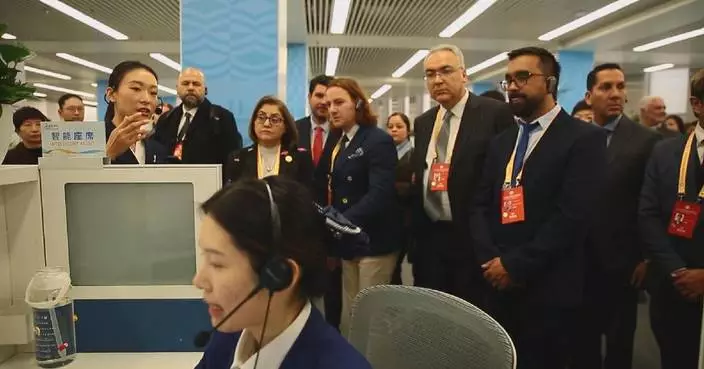

Macao has been emerging as a global hub for conventions and exhibitions in recent years by exploring the enormous opportunities in the sector, driving the region to advance its economic diversification and embrace a brighter future.

Macao has received many awards this year, such as the Best Convention City (Asia) and the Best BT-MICE City, showcasing the recognition for and influence of Macao's exhibition industry.

More than 1,000 electronic game enthusiasts from all over the world gathered recently in Macao to participate in a esports themed event.

Su Zhili, organizer of the event, said that Macao's rich experience in hosting large-scale events, coupled with its good infrastructure, has driven him to choose the region as an ideal destination to hold such an activity.

"Macao has held many similar large-scale events. It has rich experience, and the facilities at the venue are relatively mature, so we can start our work comfortably," said Su.

During the first three quarters of 2024, Macao held more than 1,000 conferences and exhibitions in total.

"We will invite more professional, special conferences to be held in Macao and also cultivate more exhibition brands with international influence in Macao, so as to promote Macao's exhibitions to be more market-oriented, professional, international, digital and greener from various aspects. This is our goal," said Elaine Wong, member of the Macao Commerce and Investment Promotion Institute.

In addition, multiple large exhibitions and conferences, such as the Macao International Trade and Investment fair, the Macao Franchise Expo, and the International Infrastructure Investment and Construction Forum, are held regularly in Macao.

With the introduction of a series of policies and measures to facilitate the exchanges between the mainland and Macao, as well as the construction and development of the Guangdong-Hong Kong-Macao Greater Bay Area and the Guangdong-Macao In-Depth Cooperation Zone in Hengqin, Macao's convention and exhibition industry will embrace more opportunities for development in the foreseeable future.

"We have such a good industrial base in the Greater Bay Area. The mode of 'Convention and Exhibition + Industry' not only integrates the industries of Macao, but also the industries of the Greater Bay Area. In addition, Macao actively integrates into the national development and plays a role in the Belt and Road. Why are we so confident in Macao's convention and exhibition sector? Because it is backed by the motherland, and the country gives Macao great support," said Alan Ho, chairman of the Macao Association of Convention, Exhibition and Tourism Sectors.

Macao emerges as global hub for conventions and exhibitions, driving economic diversification and international recognition