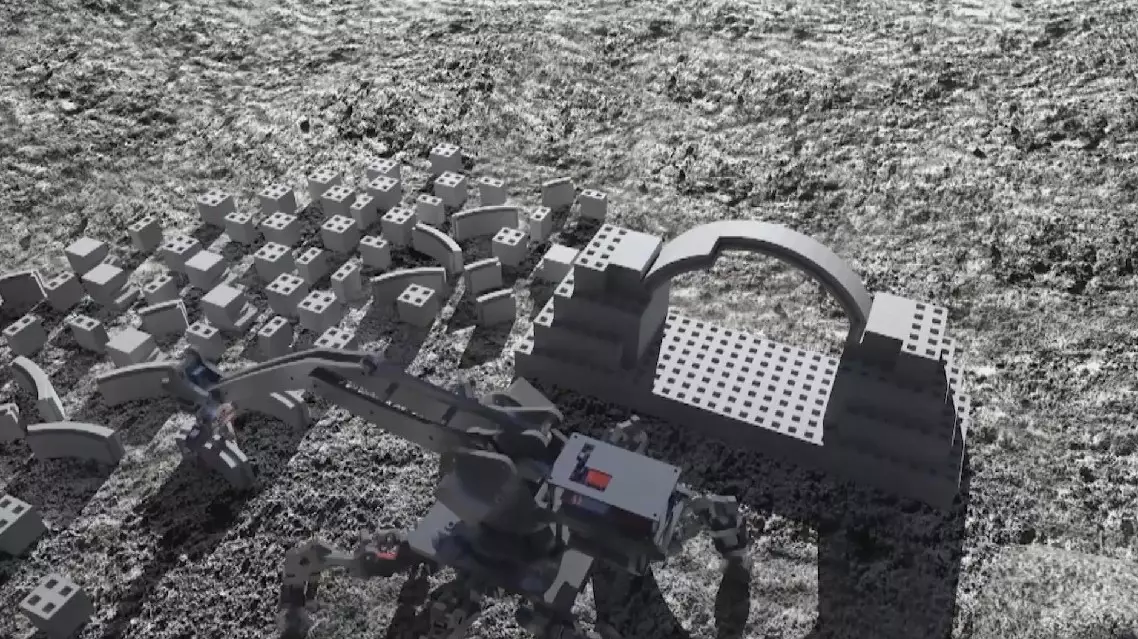

China has taken a significant step towards building a lunar base by sending simulated "lunar bricks" to the Tiangong space station for exposure tests, which offers the closest environment to lunar conditions currently accessible to mankind, said the lead scientist of the experimental project.

On November 15, at 23:13 Beijing time, the Tianzhou-8 cargo spacecraft departed from the from the Wenchang Satellite Launch Center for the orbiting Tiangong space station. Just three hours later, the spacecraft successfully docked with the space station combination, delivering its payload with remarkable efficiency. Among the cargo was a unique experimental package: bricks made of simulated lunar soil.

These "lunar soil bricks," which are potential construction materials designed for future lunar bases, represent a pioneering effort by the National Center of Technology Innovation for Digital Construction (NCTI-DC) at central China's Huazhong University of Science and Technology.

In the pivotal experiment, they are now being exposed to the harsh environment of space to obtain key scientific data. Ding Lieyun, an academician of the Chinese Academy of Engineering and NCTI-DC chief scientist, spearheaded the development of these bricks.

The lunar soil bricks delivered to the space station were made from five different simulated lunar soil compositions with three distinct sintering methods. Apart from the bricks, an operational guide for conducting the exposure experiments was also sent.

"[The bricks] will be placed outside the Wentian module for exposure experiments, where they will be subjected to cosmic radiation and repeated thermal vibrations, experiencing temperatures ranging from -100 degrees Celsius to over 100 degrees Celsius. These experiments will help us comprehend their degradation over time," said Professor Ding.

"Once a building is erected, we anticipate its longevity to extend far beyond just a few years. Given that the project will be on the Moon, it is imperative that we gain a comprehensive understanding of how materials age in such an environment. Only through this understanding can we establish standards [for lunar construction]," he added.

The scientist said there are three sample boards sent into space, with one retrieved each year for performance analysis.

Research shows that lunar soil is a mix of rock fragments, minerals, glassy particles, and adhesives, varying from region to region across the Moon's surface. On Earth, volcanic ash from northeast China's Changbai Mountains is close to the lunar soil composition and has been used to create simulated lunar soil for experiments. Lunar soil contains various minerals with different melting points, so it is necessary to determine the optimal sintering temperature range to ensure that the lunar bricks achieve the required strength for construction materials.

"After analyzing the mineral composition of various lunar soils, we discovered that their melting points range from approximately 600 degrees Celsius to nearly 2000 degrees Celsius. So, we initiated sintering tests beginning at 600 degrees Celsius. Through our experiments, we observed that the material's performance plateaued beyond 1200 degrees Celsius. This finding led us to ascertain that the best range falls between 1000 degrees Celsius and 1100 degrees Celsius. In the second phase, we employed 10-degree Celsius increments between that range—1010 degrees Celsius, 1020 degrees Celsius and up to 1100 degrees Celsius. Ultimately, our efforts revealed that the most suitable range lies between 1050 degrees Celsius and 1060 degrees Celsius," Ding said.

Ding's team also completed the tests for three types of sintering methods: vacuum sintering, inert gas sintering, and air sintering. Among them, inert gas sintering generated the highest material strength, exceeding 100 MPa. While in a vacuum environment, effective sintering can be achieved by heating the simulated lunar soil to temperatures between 1000 and 1100 degree Celsius. And the sintering time can be further shortened through pressurization.

"The data collected on Earth serves as a reference for determining temperature ranges in upcoming experiments on the Moon, given the limitations on conducting tests in that environment directly. Once we establish the fundamental principles, we can streamline the trial-and-error process on the lunar surface. By conducting certain experiments on Earth, we can significantly reduce the expensive payload costs linked to such tests on the Moon," Ding said.

Since the successful Apollo 11 mission in 1969 that marked the first human landing on the Moon, lunar exploration has never stopped. The deployment of simulated lunar soil bricks to space aboard Tianzhou-8 is expected to provide vital data for the construction of future lunar bases.

"The environment of the space station closely resembles that of the Moon among the locations humans can reach at present, as the two most important factors affecting the degradation mechanism are nearly the same on both places. While the space station environment is not an exact match to the Moon's, it's still the closest approximation available to us. In this sense, at least we will come to another conclusion and take a step forward," said the scientist.

Lunar bricks' space test paves way for China's moon base construction: scientist