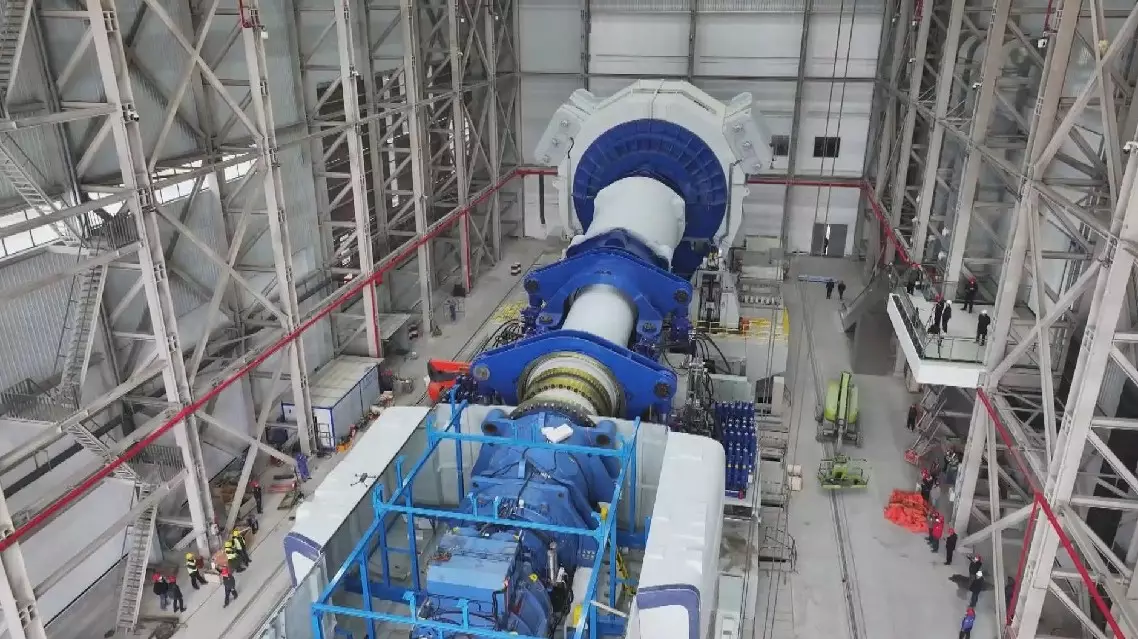

China's first full-scale onshore testing platform for offshore wind turbines was put into use on Thursday in east China's Fujian Province, showcasing world-leading abilities.

Consisting of multiple cutting-edge equipment, the platform can simulate complex offshore working environments of wind turbines to test their quality and performance, with a maximum simulation capacity of 27.5 megawatts (MW).

"The experimental platform can provide 35 meganewton-meters (MNm) of torque, which is the largest capacity among all platforms worldwide. This means that we can simulate a force environment for the world's largest-set wind turbines, whose capacities are 20 megawatts, under the effect of a level 18 typhoon to test their performance," said Qin Shiyao, deputy director of the New Energy Institute under the China Electric Power Research Institute.

To improve its adaptability, researchers developed adjusting systems to fit turbines of different angles.

"Since the pitch angles of the offshore wind turbines being tested vary for each model, we have developed a system that integrates hydraulics, electrical components, and control, allowing us to freely adjust the 1,200-ton motor within a range of 6 to 10 degrees, with an adjustment precision of 0.01 degrees. This has never been achieved internationally," said Xue Yang, head of the Offshore Wind Power Digitalization Technology Laboratory, Fuzhou Branch of China Electric Power Research Institute.

Different from previous on-the-spot testing methods, the platform provides a controllable and more comprehensive environment to test the performance of wind turbine under extreme winds, significantly shortening the time.

"In the past, our tests were mainly carried out by installing turbines offshore, and the testing was highly dependent on weather conditions. With this test platform, we can more comprehensively test the operational conditions of wind turbines. The original testing time, which took half a year to a year, can now be shortened by more than half," said Xue.

Researchers are also planning to upgrade the platform with digital technologies, aiming to facilitate the development of new-type wind turbines.

"We are also building a digital twin platform that will help verify and optimize the design and development of wind turbines. In the future, it will also support the development of larger-capacity turbines," said Xue.

China's first onshore testing platform for offshore wind turbines put into use

China's first onshore testing platform for offshore wind turbines put into use