Fueled by the artificial intelligence (AI) and other data-driven industries, the rapid expansion of the digital economy in Hangzhou, home city of China's tech giant Alibaba and startup DeepSeek, has driven a sharp increase in electricity consumption and higher demands for stable power supply.

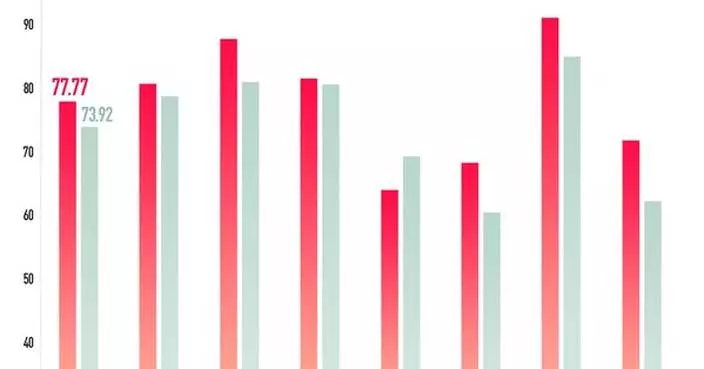

In the first two months of 2025, electricity consumption in the internet data service sector of Hangzhou, capital of east China's economic powerhouse province of Zhejiang, surged by 231 percent year on year. Key data centers across the city were the main drivers of this growth, with their power consumption growth rates outpacing that of the city's overall electricity demand.

"The internet and related sectors now are the primary contributor to Hangzhou's rising power consumption, accounting for 50.03 percent in the past two months. This growth has strongly supported the city's high-quality economic development," said Wang Yanyan, a data analyst at the Hangzhou Energy Big Data Evaluation and Application Research Center.

In addition to the sharp rise in electricity consumption, high-tech enterprises are requiring stabler power supply and higher electric power quality.

Among these firms is Nurotron, a company based in Yuhang district of Hangzhou specializing in manufacturing neural electrical stimulation therapy and rehabilitation products.

During the laser welding of a receiver coil for a cochlear implant, over 500 welding points are packed into an area smaller than a fingernail. Any slight vibration of the welding machine can result in significant product failures.

"Even a 0.01-second fluctuation in power supply can affect the quality. If the product fails to meet standards, the losses could run into millions," explained Tan Zhiping, a technical director at Nurotron.

To meet the demand for power stability of the high-tech industries, Hangzhou has introduced a new power distribution network featuring a dual-loop design, known as the "double-petal structure". With this system, which interlinks four 10-kilovolt power lines, the reliability of power supply doubles compared to a conventional grid structure.

"If one line fails, the other line within the 'petal' instantly takes over. It is precisely this mutual backup and instantaneous takeover mechanism between the 'petals' that isolates faults within milliseconds, ensuring uninterrupted power supply to users in the affected area," said Xia Hongjun, head of the operation and maintenance division at State Grid Yuhang company.

The city has also rolled out a digital twin power grid, enabling real-time monitoring and analysis of over 3,800 substations to enhance efficiency and reliability.

Hangzhou's digital boom spurs power consumption