Chinese manufacturing has undergone a remarkable transformation, with numerous Chinese companies not only meeting but also exceeding international standards across a wide array of industries. This impressive advancement has enabled Chinese manufacturers to establish new benchmarks and gain global recognition for their exceptional capabilities.

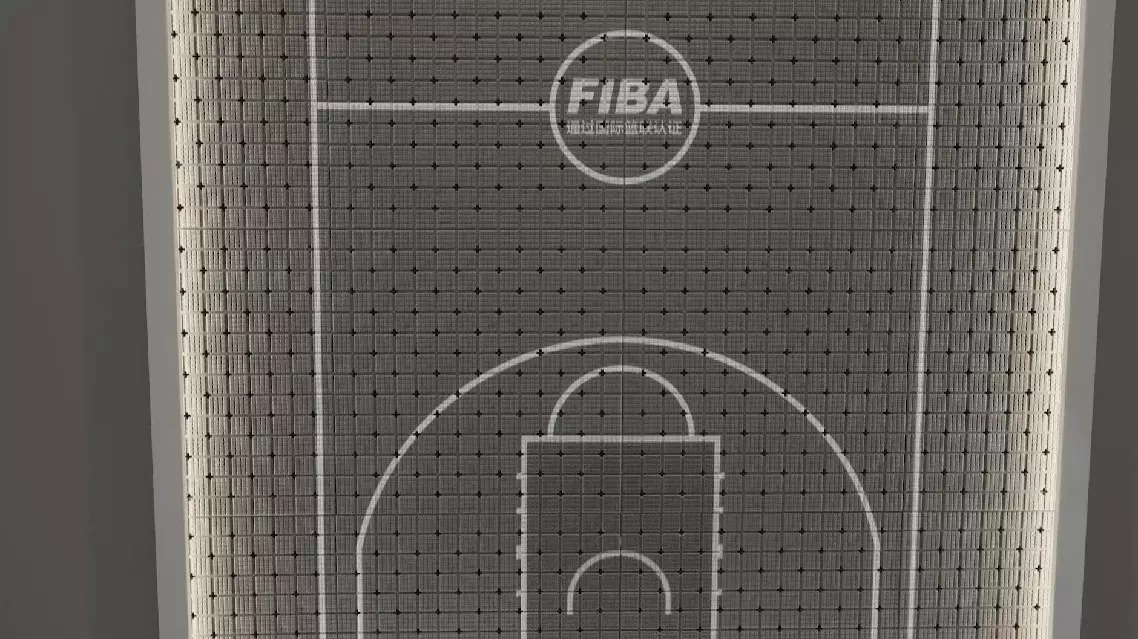

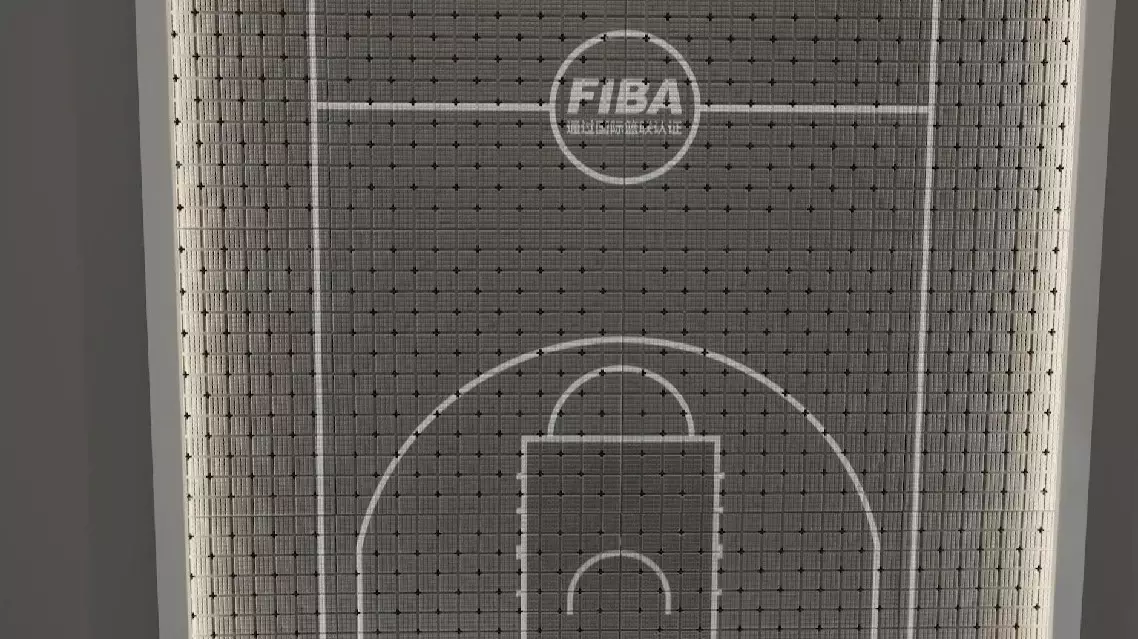

As the official supplier of 3x3 basketball and table tennis flooring for the Paris Olympics, Enlio has become the top choice for global sports events thanks to its superior product quality and innovative capabilities.

Liu Jiajia, research and development director of Enlio, said that the superior quality of their products stands as a resounding endorsement of the company's remarkable manufacturing prowess.

"In terms of performance, there have been significant upgrades in reducing hardness, enhancing anti-slip properties, and improving impact absorption to protect athletes. The second aspect is the product's eco-friendliness. We are currently collaborating with FIBA on research into bio-based materials," said Liu.

Developed by Enlio, this rubber elastic flooring is the world's first sports flooring to be officially certified by FIBA 3x3. Through close collaboration with international sports organizations, Enlio continuously refines its products to meet the demands of sports events in different countries and regions.

"The cooperation will delve into jointly developing products. We aim to ensure high professionalism and superior product quality. We are committed to elevating 'Made in China' to a recognized brand and ensuring that the world takes notice," said Hao Lihui, overseas general manager of Enlio.

In 2008, at the Beijing Olympics, ZKC Barbell made its debut, breaking a six-Olympics-long monopoly held by Japanese companies in barbell supply. Now, ZKC is set to serve the Olympics for the fourth time. The company's continuous technological advancements and consistently superior product quality have made it a favorite on the international stage.

"The primary objective of the research and development is to enhance the performance of weight plates by refining the rubber formulation and manufacturing processes. This includes optimizing the material ratios to improve tear resistance, lifespan, aging resistance, density, and hardness. The innovative integration of core materials with the rubber through a proprietary one-step molding technique not only speeds up production but also addresses the issue of weight plate imbalance," said Zhang Yi, deputy general manager of ZKC Barbell.

The competition weight plates from China now boast a weight error margin of less than 0.5 percent, surpassing the International Weightlifting Federation's standard of 1 percent.

Additionally, the bending value of the barbell shaft is within 0.2 millimeters, an improvement of 0.3 millimeters over the standards set by the International Weightlifting Federation.

"The company devotes approximately 15 percent of its annual sales to research and development, making it the sole enterprise dedicated to establishing a production line specifically for weight plates. We continuously enhance product quality in terms of technical specifications, safety, and environmental sustainability," said Zhang Zhiguo, general manager of ZKC Barbell.

In addition to Enlio and ZKC Barbell, several other Chinese companies have demonstrated their manufacturing capabilities at the Paris Olympics. From cutting-edge competition equipment to athlete gear, Chinese manufacturing has set a new benchmark for excellence in quality and innovation.

Chinese manufacturers redefine excellence at Olympic Games

Chinese manufacturers redefine excellence at Olympic Games