The application of artificial intelligence (AI) and sustainability during production are key factors in evaluating manufacturers for the list of global "lighthouse" factories by the World Economic Forum (WEF), said an expert.

The WEF, along with consulting firm McKinsey, launched the Global Lighthouse Network in 2018 to identify manufacturers that are actively pushing toward the "fourth industrial revolution" by pursuing high efficiency, intelligence and green technologies.

A total of 22 manufacturing enterprises from 10 countries joined the network in the recently released list of additions, three of which are "sustainability lighthouses," all Chinese enterprises.

Through the application of technologies such as AI and the Internet of Things (IoT), as well as process innovations, these firms have reduced direct or indirect carbon emissions by over 20 percent, leading the world.

SANY Renewable Energy, a global provider of comprehensive wind power solutions, made the list after applying various digital tools in different links of production.

At its factory in Shaoshan City, central China's Hunan Province, a single wind turbine can be around 100 meters long. Some traditional companies may struggle to monitor the production and management process, but for the world's first lighthouse manufacturer in the wind power sector, it becomes easier with digital tools.

The factory can achieve 360-degree comprehensive monitor and conduct delicate management on the real-time operation and the production parameters at various links through a small tablet PC, including those on temperature, humidity, torque, grinding fineness.

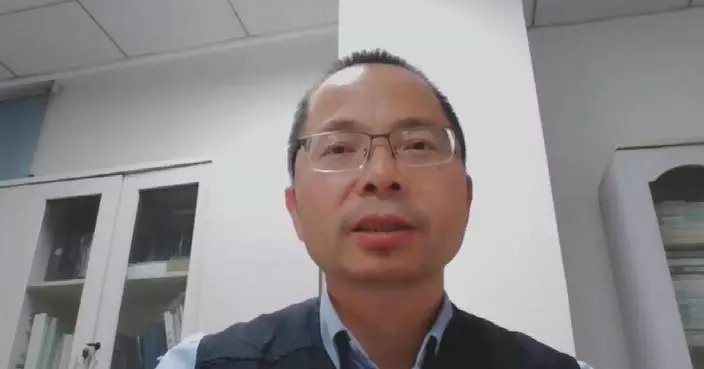

"Sunny Renewable Energy became the first lighthouse in the wind power sector because of their use of innovative technologies like AI and automation. And they are able to really demonstrate in that blade factory the company's digital solutions, including AI-driven quality management," said Kiva Allgood, head of the Center for Advanced Manufacturing and Supply Chains of the WEF.

The Global Lighthouse Network aims to inspire the global manufacturing industry by choosing manufacturers to make innovative technology transformation.

Generative AI, machine learning and other digital technologies were the key words in selecting this batch of lighthouses, according to the WEF, which estimates that the newly enlisted manufacturers have enhanced production efficiency by an average of 50 percent.

"They have to be deployed at scale within that factory. So those technologies include things like AI, IoT, robotics. And you have to have not just done a pilot. You have to have actually integrated that technology into the way that the factory works," said Allgood.

Of the 22 newly-selected lighthouse factories, 13, or nearly 60 percent are Chinese factories, marking a historic high. These factories are in sectors including new energy, pharmaceuticals and dairy products.

As of now, the total number of lighthouse factories worldwide has risen to 172, of which 74, or 43 percent of the total are from China.

"We're super excited that, again, more and more of Chinese factories are also picking up these practices, which underscores the country's ongoing efforts to drive both operational efficiency and environmental responsibility," said Allgood.

China's manufacturing sector is transforming quickly with greenness and intelligence, while generating more productivity. In 2023, the manufacturing sector contributed over 26 percent of its GDP and accounted for 30 percent of the world.

Application of AI, sustainability key for Chinese manufacturers named as "lighthouses"