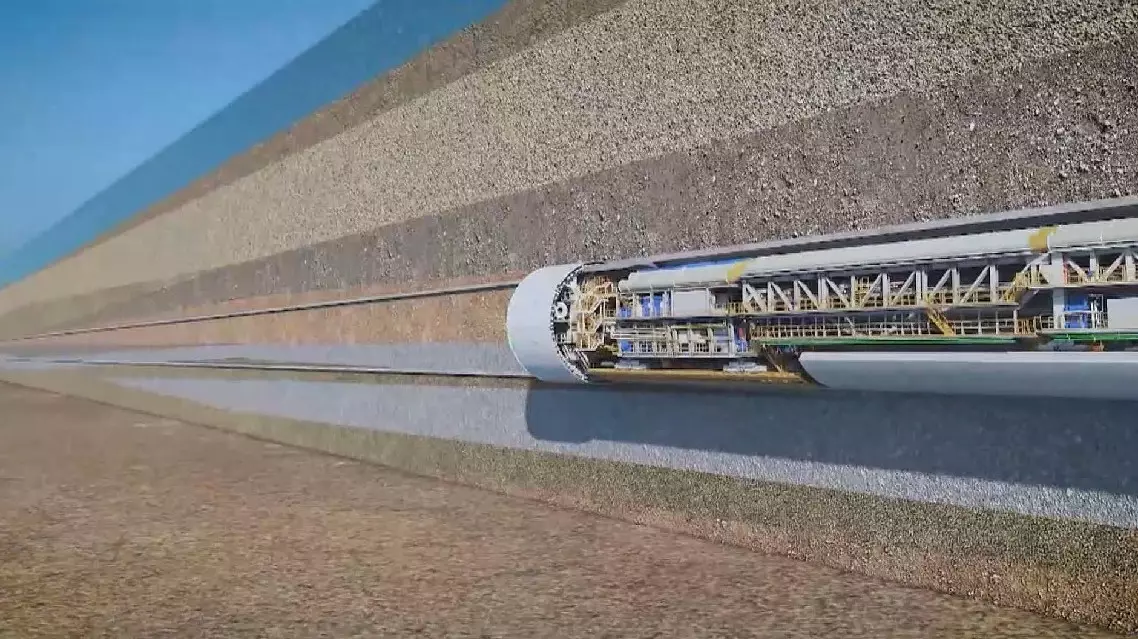

China's self-developed tunnel boring machine (TBM) with the biggest diameter on Friday achieved a significant milestone by surpassing 3,000 meters in its excavation of a large-scale tunneling project under the Yangtze River, showcasing the country's growing construction capabilities featuring high-speed and intelligent techniques.

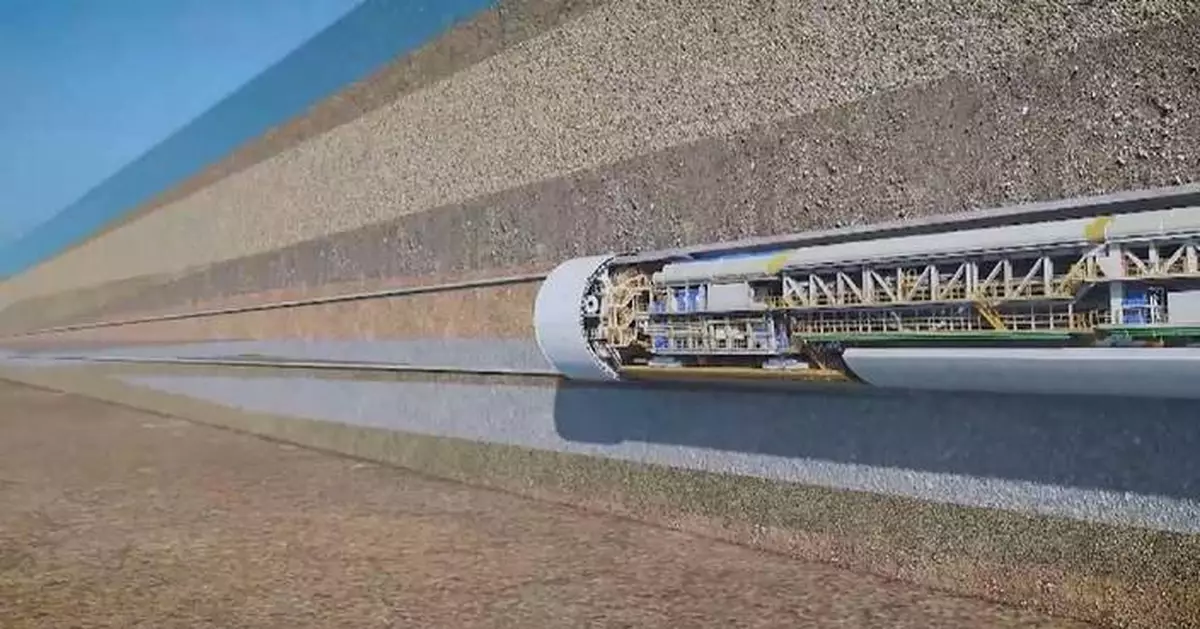

The machine, with a maximum excavation diameter of 16.64 meters, was developed jointly by the China Railway Construction Heavy Industry Co., Ltd. (CRCHI) and China Railway 14th Bureau Group Co., Ltd. It is 145 meters long and about 5,000 tons in weight. Its circular cutter's diameter is equivalent to a five or six-story building.

Under the waters of the Yangtze River estuary, the TBM is currently advancing at an impressive average speed of 600 meters per month. This remarkable progress is made possible by the application of a fully upgraded intelligent system in the TBM.

Inside the operator's cabin of the TBM, what once required two or three personnel to manage is now overseen by nobody. A nearby worker can control the entire excavation process with just a flick of a finger, allowing for fully automated and intelligent tunneling operations.

"The previous smart excavation methods primarily focused on controlling the posture of the TBM, requiring manual coordination across various systems. Now, we have all the systems linked together. This makes the process more precise, efficient, and safe," said Xu Weiqing, project manager for the Chongming-Taicang Yangtze River Crossing Tunnel.

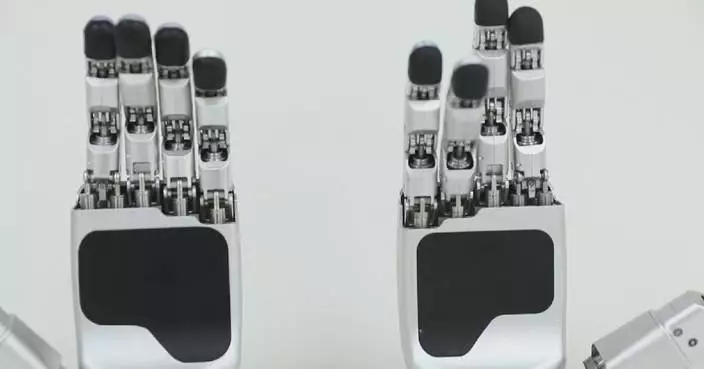

Notably, the tunnel lining segments are produced using China's first fully digital production line, increasing efficiency by 20 percent. Furthermore, with the help of self-developed intelligent assembly robots, tunnel components can be assembled automatically at the push of a button, achieving a precision control of up to 0.5 millimeters.

In addition, the intelligent upgrades extend across nine major systems involved in the construction of the TBM tunnel, enhancing processes from design and perception to transportation.

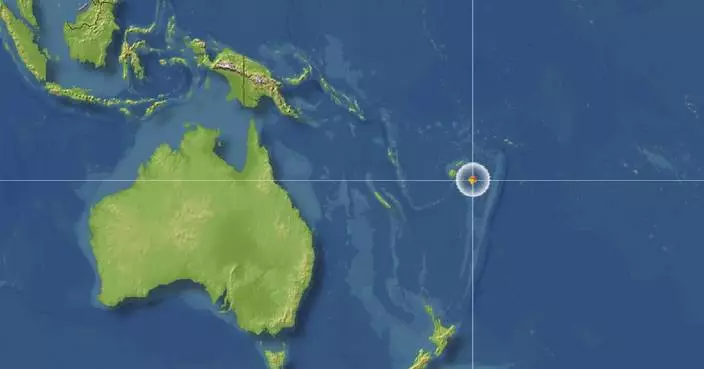

"The nine major systems utilized in tunnel construction have rapidly advanced due to the widespread application of intelligent technologies. This has propelled tunnel excavation engineering forward and ushered in a new phase in tunnel construction technology," said Xie Lili, an academician at the Chinese Academy of Engineering. The Chongming-Taicang Yangtze River Crossing Tunnel, spanning a total length of 14.25 kilometers and connecting Chongming District in Shanghai with Taicang City in east China's Jiangsu Province, features a shield section measuring 13.20 kilometers. Designed for speeds of up to 350 kilometers per hour, it is expected to be operational by the second half of 2029. Upon completion, the tunnel is poised to enable seamless high-speed train crossings under the Yangtze River, holding significant importance for driving development in the Yangtze River Economic Belt.

Innovative tunneling machine propels China's modern construction