China has made multiple technological breakthroughs in the production progress of its first self-developed civil airship, the AS700 "Xiangyun".

Last month, the AS700 "Xiangyun" carried out a successful maiden ferry flight in central China's Hubei Province to verify its flight communication, facility loading and takeoff and landing capabilities.

According to its developer -- the Aviation Industry Corporation of China (AVIC), the single-capsule manned airship has a maximum capacity of carrying 10 passengers, including a pilot.

It can fly at a height of 3,000 meters, with a maximum flight range of 700 km, and a maximum endurance of 10 hours.

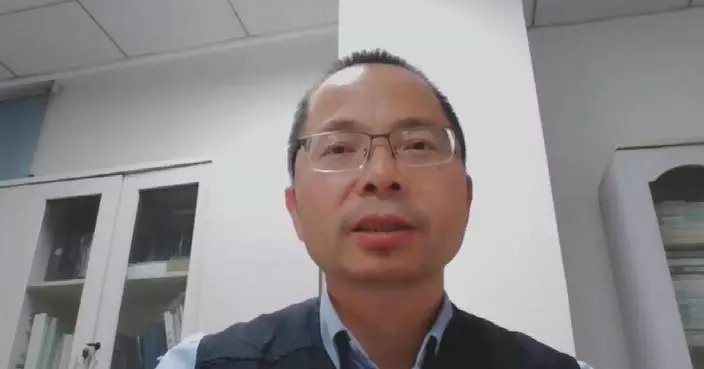

With a maximum flight speed of 100 km per hour, the airship will be mainly used in tourism, aerial survey, patrol services and emergency communication. According to Zhang Hua, senior engineer with the Special Vehicle Research Institute of AVIC, the capsule of AS700 is made of home-made non-metallic multilayer composite materials. The configuration design of the capsule ensures that the airship can land on the ground safely even if the capsule is damaged.

"In the past ten years, many capsule materials have been domestically produced. Even if it's broken, the air will slowly leak out, which ensures that the airship can fly back safely," Zhang said.

In order to make the flight more stable in the air, the research team has also solved key technology problems regarding flight control and developed a leading thrust-vector-control technology, making the takeoff and landing of the AS700 smoother and more accurate.

"After the adoption of this technology, we can take off and land in short distances or even vertically, which reduces reliance on traditional takeoff and landing sites. We can use a site to do vertical takeoff and landing as long as the surface is flat and we don't even have to do it at airports," said Zhang.

According to the AVIC, the first commercial AS700 is scheduled to be delivered by the end of this year.

China-developed AS700 airship sees multiple technology breakthroughs