With its rapid pace of innovation and development, China has been attracting multinational companies to invest in manufacturing and research bases to explore its grand domestic market and seek new momentum.

Schneider Electric, a global industry leader, has put China at the center of its global operations. With its "China Hub" strategy, Schneider integrates local research and development, manufacturing, and supply chain capabilities to meet both domestic and international demand.

The company has established five major research and development centers and an AI innovation lab in China, with its Shanghai center expanding to 14,000 square meters and with hundreds of researchers.

"China is not only a huge market but also a driving force of development and a source of innovation for us. With the support of China's industrial development and innovation advantages, Schneider Electric's research outcomes and new products developed in China have been promoted globally, bringing Chinese wisdom to the world," said Yin Zheng, executive vice president of Schneider Electric and president of its East Asia Zone.

Meanwhile, the rapid transformation and innovation of China's automotive industry has attracted global attention. Taiji Toyota, former director of the Nissan China Technology Center and now the design director at IAT Automobile, a Chinese new energy vehicle (NEV) brand, attributes the rapid changes and renovations in the Chinese automotive sector as a key reason for his decision to join a Chinese company.

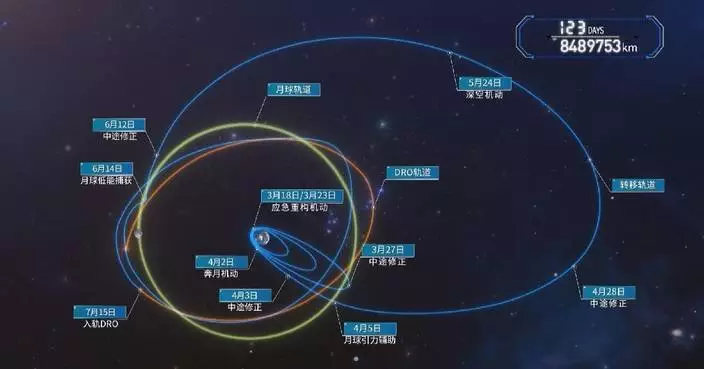

"(Chinese) people have (been) dramatically changing (expectations) on the car. Autonomous driving is become popular now. For example, in some countries, the developing task (requires) four years. But in here, two years. So this kind of speed is really important to advance. That's the biggest (reason) for me to be a designer in China. There's more chance to make my dream come true," said Toyota. In addition, an increasing number of foreign companies are targeting the rapid development of China's new energy vehicle sector. Recently, IAT signed a six-year agreement with a Japanese automaker to collaborate on vehicle development, auto parts, and system development.

"A typical electric vehicle consists of hundreds of assemblies and thousands of components. If we utilize Chinese components and their supporting systems in our supply chain, the BOM (Bill of Materials) cost would be 30 percent lower than if we used the current Japanese parts and systems," said Xuan Qiwu, chairman of IAT.

Taking the chance of AI development, IAT has also integrated AI technology into its vehicle design process, which allows faster production of multiple design solutions to meet the customized demands of global clients.

"Previously, we typically created 3D models and then rendered them in a rendering software, which took over a month. However, empowered by AI, individuals can now accelerate the drawing process by at least 50 percent," said Wang Shiyu, AI head at IAT Vehicle Styling Studio. Thanks to its efficient innovation capabilities and robust supply chain system, China's electric vehicle industry has featured high-quality, low-cost, and rapid innovation, positioning itself as a leader in the sector.

"With the electrification and intelligence (of vehicles), we have witnessed a complete integration of the smartphone, automotive, software, and sensor industries, resulting in a powerful, reliable, low-cost, and high-quality supply chain for the automotive sector," said Xuan.

China attracts global enterprises with rapid innovation